Design · Model · Manufacture

Design · Model · Manufacture

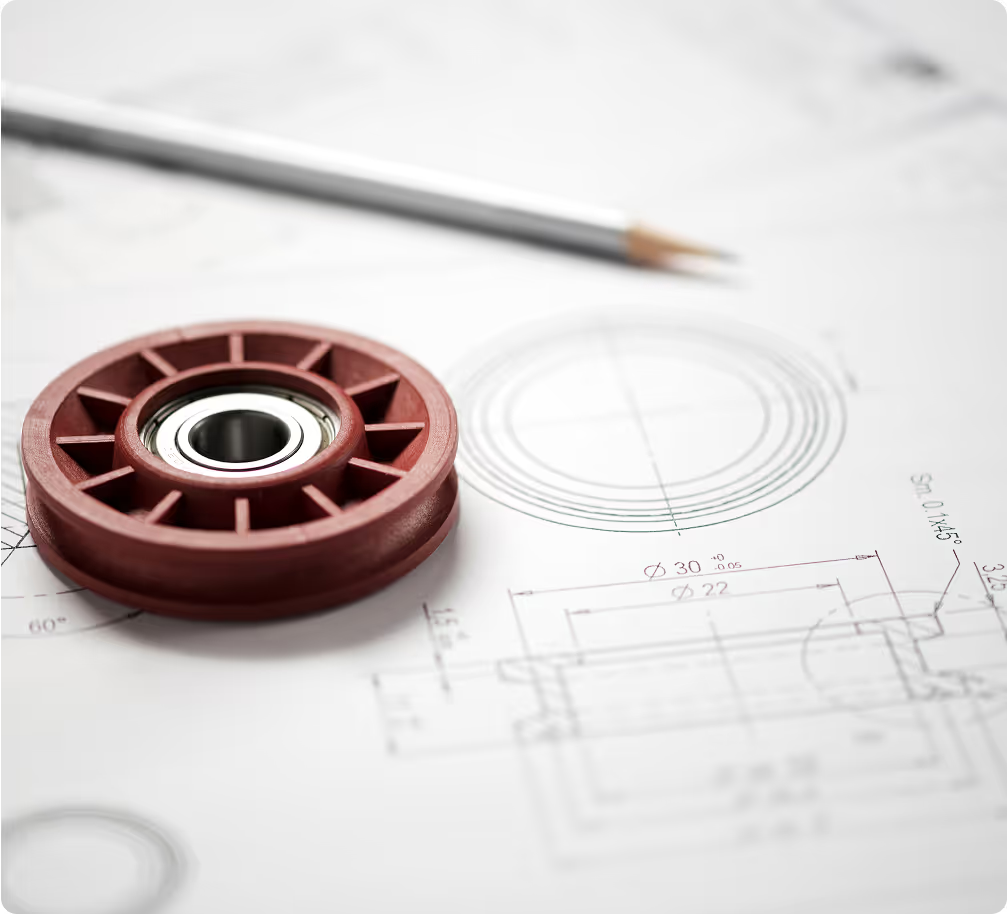

CAD Design Services

Professional CAD for Manufacturing

Transform your technical requirements, legacy parts, or design concepts into production-ready CAD files. We deliver precise, manufacturable models optimized for your chosen production method.

Your Ideas, Made Real

Whether you're an inventor with a sketch, a business owner with a broken part, or an engineer without time — we take your starting point and deliver production-ready files.

Design Custom Solutions

When off-the-shelf doesn't cut it, we design exactly what you need. Brackets, mounts, adapters, housings, jigs — custom parts designed for your specific application, constraints, and manufacturing method.

See how we designed a custom drone catch handle →

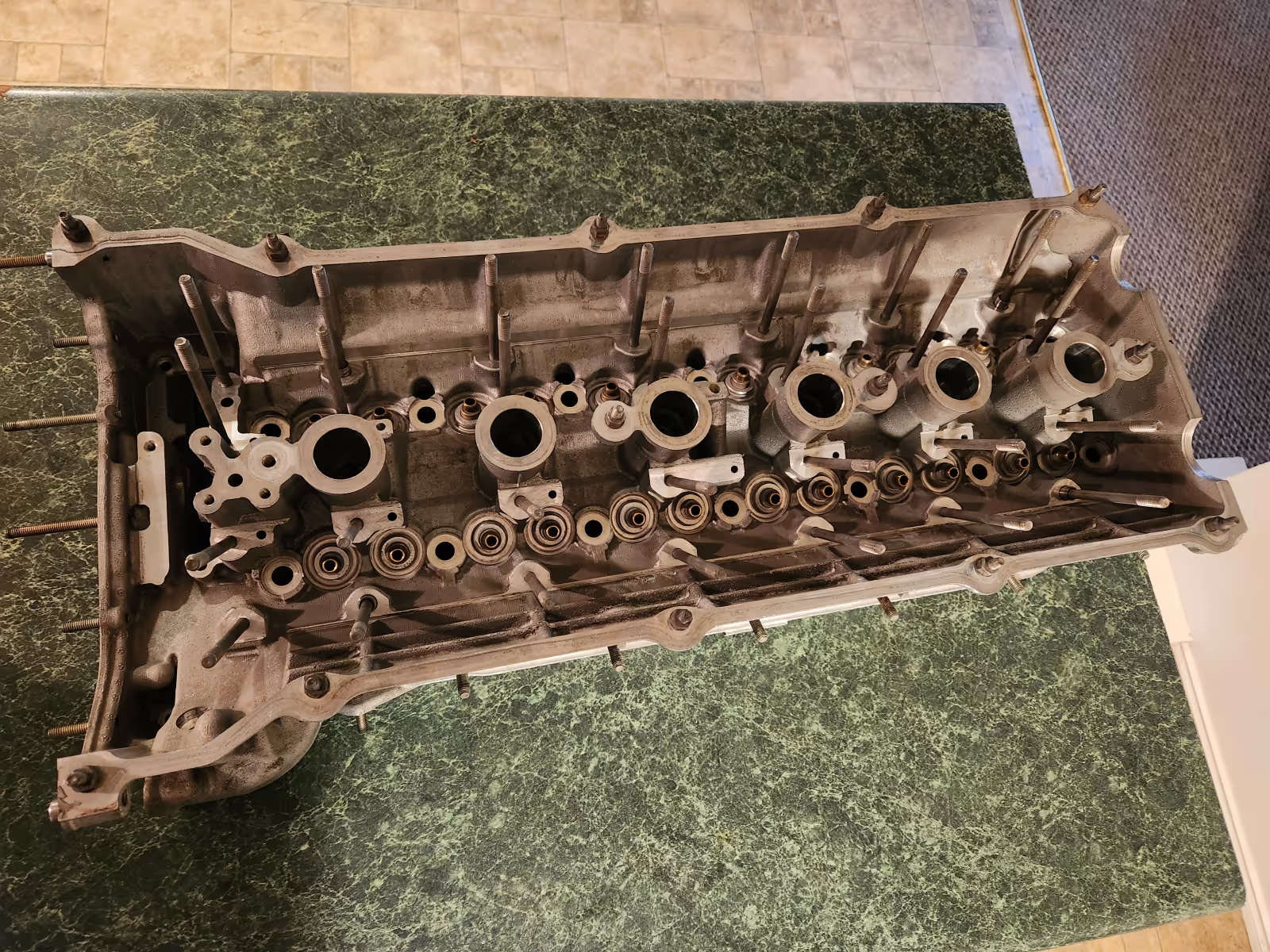

Recreate Parts Without Drawings

Have a broken or worn part with no CAD file? If you have the physical object, we can scan it and rebuild it in CAD — fixing damage, improving the design, or just creating an exact replica ready for manufacturing.

Learn about our 3D scanning services →

Launch Your Product Idea

Got a product concept but no CAD skills? We work with entrepreneurs, inventors, and small businesses to turn rough ideas into refined 3D models ready for prototyping. See it, hold it, test it — then decide if you're ready to scale.

We Make the Complex Simple

You focus on what you're building and why. We handle the technical translation.

What This Means For You

- Designed for manufacturing: We optimize for your production method, whether it's 3D printing, CNC, or injection molding

- Iterate with confidence: We provide previews and revisions so you see exactly what you're getting

- Own your files: You receive editable, production-ready files in standard formats. You retain full ownership, and your designs are protected under Canadian IP law.

- End-to-end support: Need it printed or machined? We can manufacture it too — all under one roof

From Concept to File in 5 Steps

You bring the idea — a sketch, a photo, a broken part, or just a description. We handle the rest.

Share Your Vision

Tell us what you're building and what it needs to do. Send sketches, photos, and measurements. The more you have the quicker we can get started.

We Ask Questions

We'll follow up to understand the use case, constraints, and manufacturing plans. This ensures the design works in the real world, not just on screen.

Review the First Draft

We build an initial model and send you renders or a physical prototype. You tell us what's working and what needs adjustment.

Refine & Finalize

We incorporate your feedback, dial in tolerances, and optimize for your chosen manufacturing method. The model is reviewed until you're happy.

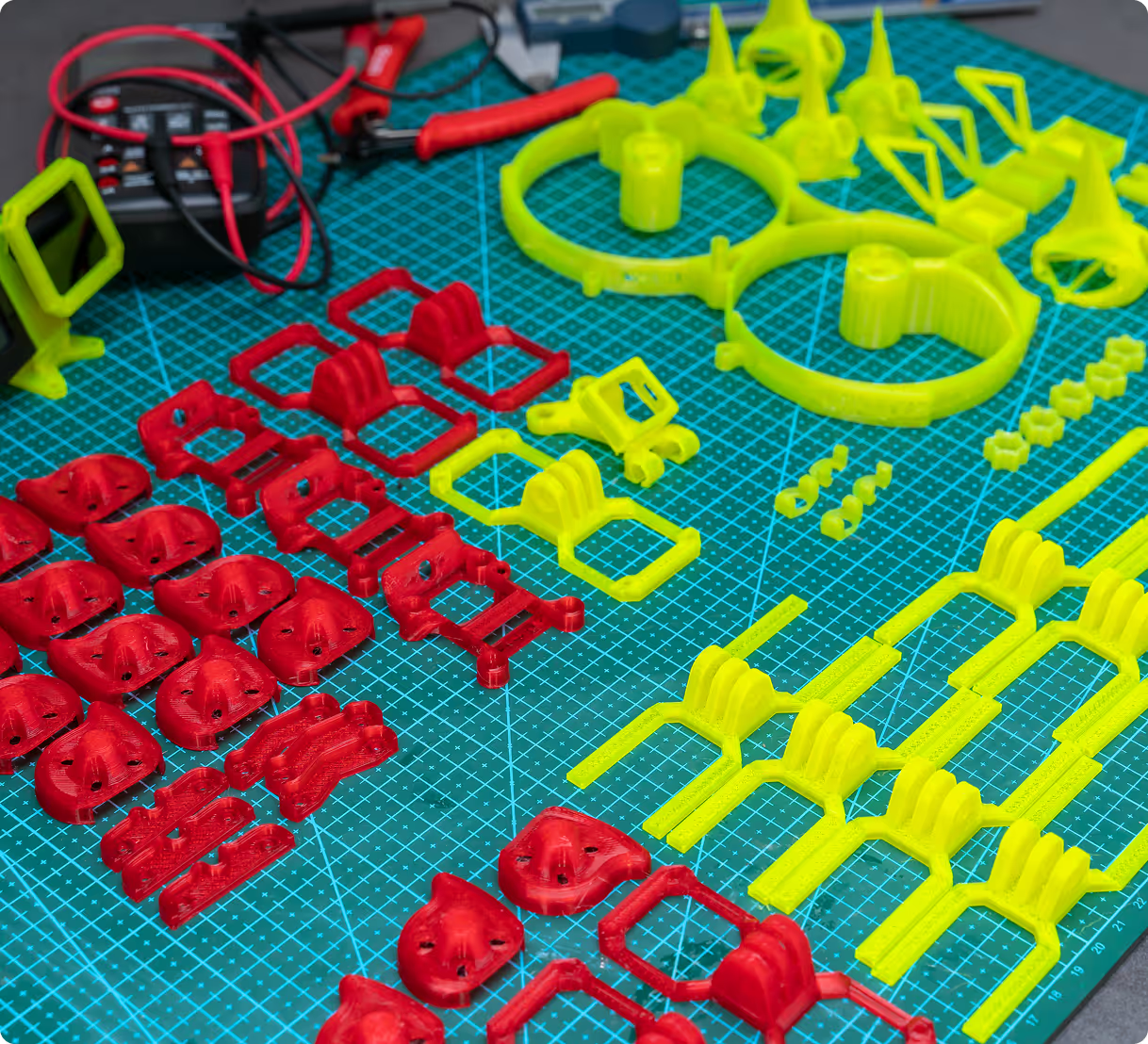

Custom Drone Catch Handle for Marine Conservation

The W̱SÁNEĆ Marine Guardians needed a safer way to launch and recover their monitoring drone from a moving boat. Off-the-shelf solutions didn't cut it, so we designed one.

Through rapid prototyping and iterative design, we created a custom catch handle precisely fitted to their DJI Matrice M30. Ergonomic, sensor-safe, and built to withstand corrosive ocean conditions.

The Outcome

- Safer launch and recovery operations

- Reduced risk to equipment and crew

- Uninterrupted whale-habitat monitoring

More Than Just Parts

Product Prototypes

Test your product concept before committing to expensive tooling. We design for rapid iteration and realistic functional testing.

Custom Jigs & Fixtures

Assembly aids, alignment tools, and production fixtures designed for your specific workflow. Make repetitive tasks faster and more consistent.

Replacement Parts

When the manufacturer no longer makes it and you can't find it anywhere. We recreate obsolete components from samples or measurements.

Enclosures & Housings

Protective cases for electronics, custom enclosures for sensors, waterproof housings — designed for fit, function, and aesthetics.

Design Improvements

Have an existing part that almost works? We can modify, strengthen, or optimize it. Better geometry, better materials, better results.

Technical Drawings

Need 2D drawings with dimensions and tolerances? We provide professional documentation for quoting, production, or regulatory compliance.

Files That Work Everywhere

We deliver in standard formats compatible with any manufacturer, 3D printer, or CAD system you use.

3D Printing Files

STL, OBJ, 3MF

Ready to slice and print on any FDM, SLA, or SLS printer. Optimized for the technology you're using.

CAD Exchange Files

STEP, IGES, Parasolid

Universal formats that open in any professional CAD system. Perfect for CNC programming or further development.

Native CAD Files

SolidWorks, Fusion 360, Inventor

Fully parametric, editable files. Make changes yourself or send to any engineer for modifications.

2D Drawings

PDF, DXF, DWG

Professional technical drawings with dimensions, tolerances, and annotations. Ready for quoting or production.

Common Questions

I only have a rough sketch. Is that enough to start?

Absolutely. Hand-drawn sketches, napkin drawings, even verbal descriptions — we work with whatever you have. We'll ask questions to fill in the gaps and clarify the requirements before modeling.

How long does a typical CAD project take?

Simple parts often take 1–2 business days. More complex designs, assemblies, or parts requiring tight tolerances may take 3–7 days depending on scope and feedback cycles.

Can you design something that will be 3D printed?

Yes — we optimize designs specifically for your manufacturing method. For 3D printing, that means appropriate wall thicknesses, support-friendly geometry, and material-specific considerations.

What if I have a physical part but no drawings?

We can 3D scan the part to capture its geometry, then rebuild it in CAD. This lets us create an exact replica or make modifications before manufacturing.

Do I get to keep the CAD files?

Yes. The designs are yours to do with as you please. We can also keep a copy on file for future orders.

Can you also manufacture the part after designing it?

Yes — we offer 3D printing in-house and can coordinate CNC machining, metal printing, or other manufacturing methods. Design to delivery, all under one roof.

How much does CAD design cost?

Pricing depends on complexity, number of parts, and required precision. Simple parts start around $150; complex assemblies vary. High quality dimensioned drawings help save us time, the better the source materials the quicker we can bring them to life.

What CAD software do you use?

Our team primarily works in Autodesk Inventor, Fusion, and OnShape. We can deliver files compatible with any major CAD system.

Ready to Turn Your Idea Into a Real Part?

Send us a sketch, a photo, or just a description of what you need. We'll get back to you with a quote and timeline.