FDM 3D Printing Services

Fused Deposition Modeling

Cost-effective, versatile, and fast. FDM delivers durable thermoplastic parts for functional prototypes, enclosures, brackets, tooling, and end-use applications.

How FDM 3D Printing Works

FDM (Fused Deposition Modeling) builds parts by heating thermoplastic filament and depositing it layer by layer through a precision nozzle. As each layer cools, it bonds to the previous layer, creating strong, functional parts.

This process makes FDM ideal for rapid prototyping, functional testing, and low-to-medium volume production. With a wide range of engineering-grade materials available—from basic PLA to carbon fiber-reinforced nylon—FDM offers the best balance of cost, speed, and performance for most applications.

Key Advantages

- Cost-Effective: Lowest per-part cost for most geometries

- Fast Turnaround: Most orders ship within 1–3 days

- Large Build Volume: Print parts up to 1m³ in a single piece

- Material Variety: 15+ materials including carbon fiber composites

- Functional Parts: Real mechanical strength for end-use applications

File Check & Optimization

We review your 3D file for printability, wall thickness, and geometry issues.

Slicing & Setup

Optimal parameters for layer height, infill, supports, and orientation.

Printing

Your part is built layer by layer on calibrated, industrial-grade machines.

Post-Processing & QC

Support removal, surface finishing, and dimensional verification.

FDM Materials & Properties

Choose from engineering-grade thermoplastics optimized for different applications. Each material offers unique properties for strength, temperature resistance, flexibility, or appearance.

PLA

Budget FriendlyHeat Resistance: 40°C

Vibrant colors, excellent detail, and easy to print. Ideal for visual prototypes, concept models, and decorative parts.

PETG

Most PopularHeat Resistance: 80°C

Excellent all-rounder with good strength, impact resistance, and chemical resistance. Perfect for functional parts and outdoor use.

ABS

Industrial StandardHeat Resistance: 100°C

Tough, heat-resistant, and machinable. The industry standard for mechanical applications, enclosures, and automotive parts.

ASA

Outdoor UseHeat Resistance: 105°C

UV-stable alternative to ABS. Excellent weathering resistance for outdoor applications without yellowing or degradation.

PAHT–CF

PremiumHeat Resistance: 170°C

High-temp carbon fiber nylon for demanding environments where heat and stiffness matter most.

PPS–CF

PremiumHeat Resistance: 220°C

Highest stiffness, strength, chemical resistance, and heat resistance for the toughest conditions.

PPA–CF

PremiumHeat Resistance: 230°C

Highest stiffness, strength, and heat resistance for tough conditions and structural performance parts.

PET–CF

PremiumHeat Resistance: 180°C

Extremely low water absorption for use in humid or underwater conditions. Ideal for load-bearing parts that need to perform the same wet and dry.

PA (Nylon)

High PerformanceHeat Resistance: 100°C

Excellent wear resistance, low friction, and toughness. Ideal for gears, bearings, bushings, and mechanical components.

Polycarbonate (PC)

PremiumHeat Resistance: 150°C

Outstanding impact resistance and high temperature performance. Used in automotive, aerospace, and medical applications.

PC FR

PremiumHeat Resistance: 105°C

Fire-resistant polycarbonate (UL 94-V0). For electrical and regulated use where flame retardancy matters.

PC–CF

PremiumHeat Resistance: 140°C

Carbon-fiber reinforced polycarbonate for premium stiffness and dimensional stability in aerospace and automotive applications.

PA–CF

PremiumHeat Resistance: 105°C

Carbon fiber reinforced nylon. Stiff while still having good impact resistance for functional structural parts.

ASA–CF

PremiumHeat Resistance: 110°C

Carbon fibre reinforced ASA. Stiffer and slightly more temperature resistant than standard ASA with a matte finish.

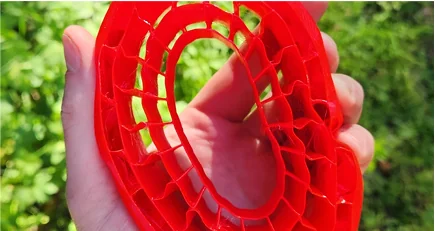

TPU (Flexible)

FlexibleHeat Resistance: 80°C

Rubber-like flexibility with excellent impact absorption. Ideal for gaskets, seals, bumpers, and soft-touch components.

Don't see what you need? We can source specialty materials on request.

Request Custom MaterialFDM Design Guidelines

Follow these guidelines for optimal results. Our team will review your file and suggest adjustments if needed.

Build Volume

Up to 1m³

In-house capability. Partner network offers up to 2100×700×900mm for larger parts.

Tolerance

±0.25mm or ±0.5%

Whichever is greater. Lower-temp materials achieve better dimensional accuracy.

Layer Height

0.05mm – 0.6mm

Standard is 0.2mm. Finer layers for detail, thicker for speed and strength.

Minimum Wall Thickness

0.6mm recommended

Minimum 0.3mm possible. Thicker walls increase strength significantly.

Infill Density

10% – 100%

Standard 20% for balance. Higher infill increases strength and weight.

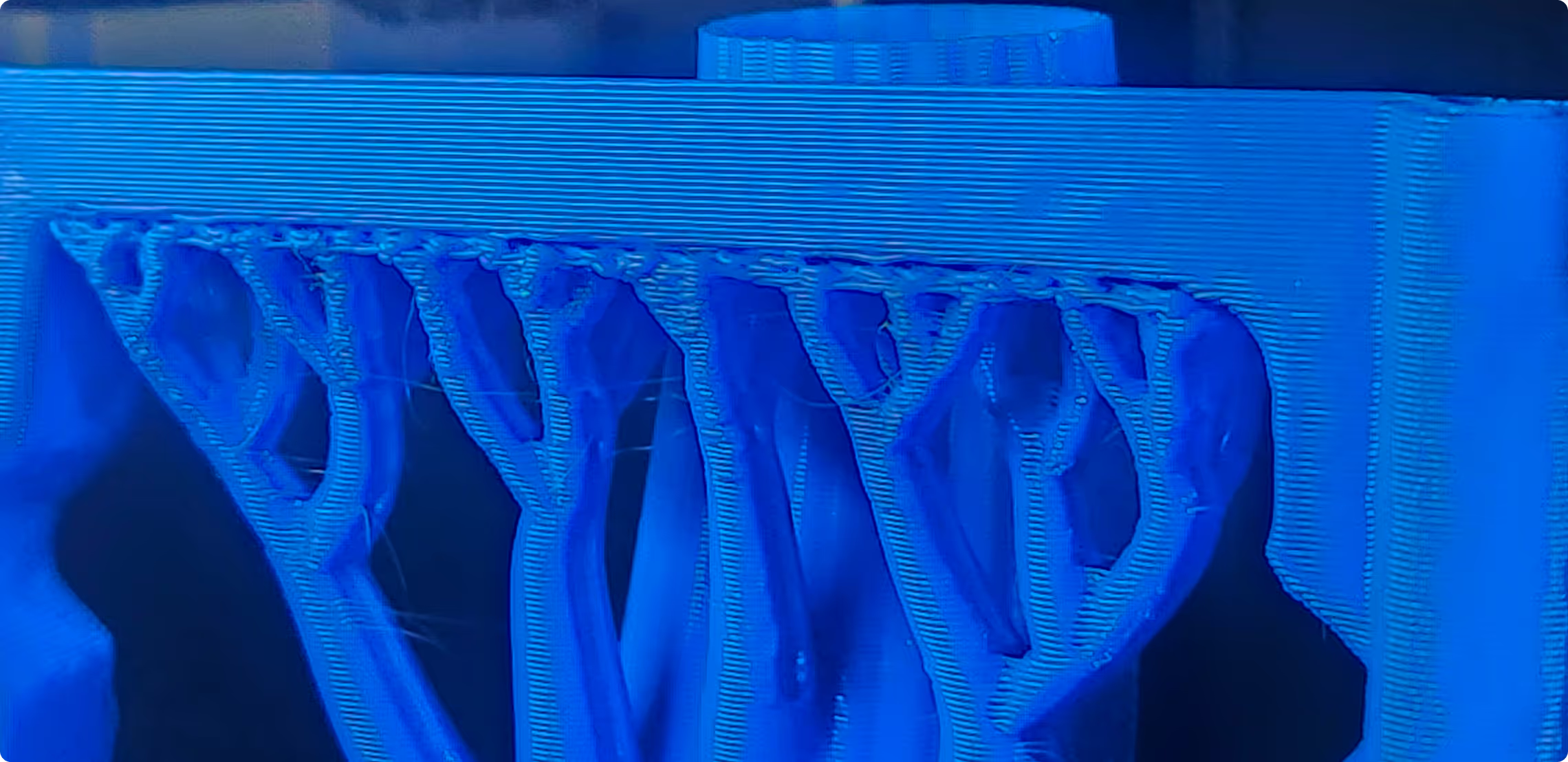

Surface Finish

Visible layer lines

Layer lines inherent to FDM. Post-processing available for smoother finish.

What FDM Is Best For

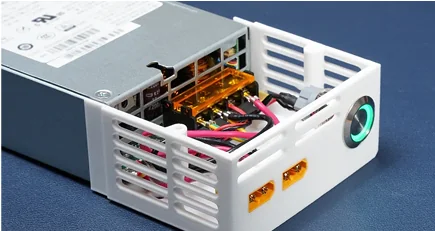

Enclosures & Housings

Custom enclosures for electronics, control boxes, and equipment housings with snap-fits and mounting features.

Jigs & Fixtures

Custom manufacturing aids, assembly jigs, inspection fixtures, and workholding solutions.

Functional Prototypes

Test form, fit, and function before committing to tooling. Iterate quickly with real materials.

Brackets & Mounts

Structural brackets, camera mounts, sensor housings, and mechanical attachments.

End-Use Parts

Production components, replacement parts, and custom tools for daily use.

Large Format Parts

Oversized components, architectural models, and large assemblies printed in sections.

FDM 3D Printing Questions

FDM vs. SLA vs. SLS – Which should I choose?

FDM is best for cost-effective functional parts, enclosures, brackets, and jigs. SLA excels at fine details and smooth surfaces for visual prototypes and molds. SLS offers superior strength and complex geometries without supports. Not sure? We're happy to recommend based on your specific requirements.

What factors affect FDM printing cost?

Cost depends on material type, part size, infill density, layer height, and post-processing. More complex or high-resolution prints take longer and cost more. We provide transparent quotes upfront with no hidden fees.

Which FDM material do you recommend?

PETG is our most popular choice—strong, weather-resistant, and versatile. For budget prototypes, use PLA. For heat resistance, choose ABS or ASA. For maximum strength, go with PA-CF (carbon fiber nylon). We'll help you select the right material for your application.

How quickly can you print and ship FDM parts?

Most FDM orders ship within 1–3 business days. Complex or large parts may take longer. We offer rush options and Canada-wide tracked shipping, plus free local pickup in Victoria, BC.

What's the maximum size you can print?

In-house we print up to Up to 1m³. Through our partner network, we can produce parts up to 2100×700×900mm. Larger objects can be split into sections and assembled cleanly.

How strong are FDM printed parts?

FDM parts can be very strong for functional use when the material, wall thickness/infill, and print orientation are chosen correctly. Keep in mind FDM is anisotropic—parts are typically strongest along the layer lines and weaker across layers. PETG and ABS/ASA work well for many applications; for higher stiffness and strength, PA-CF (carbon-fiber nylon) or PC (polycarbonate) may be a better fit with the right print settings.

Ready for FDM 3D Printing?

Upload your file, select your material, and get an instant quote. Fast, affordable, and built to last.