Metal 3D Printing Services

DMLS / Direct Metal Laser Sintering

Fully dense metal parts with high precision. Print complex geometries in stainless steel, aluminum, titanium, and superalloys—for aerospace, medical, and high-performance applications.

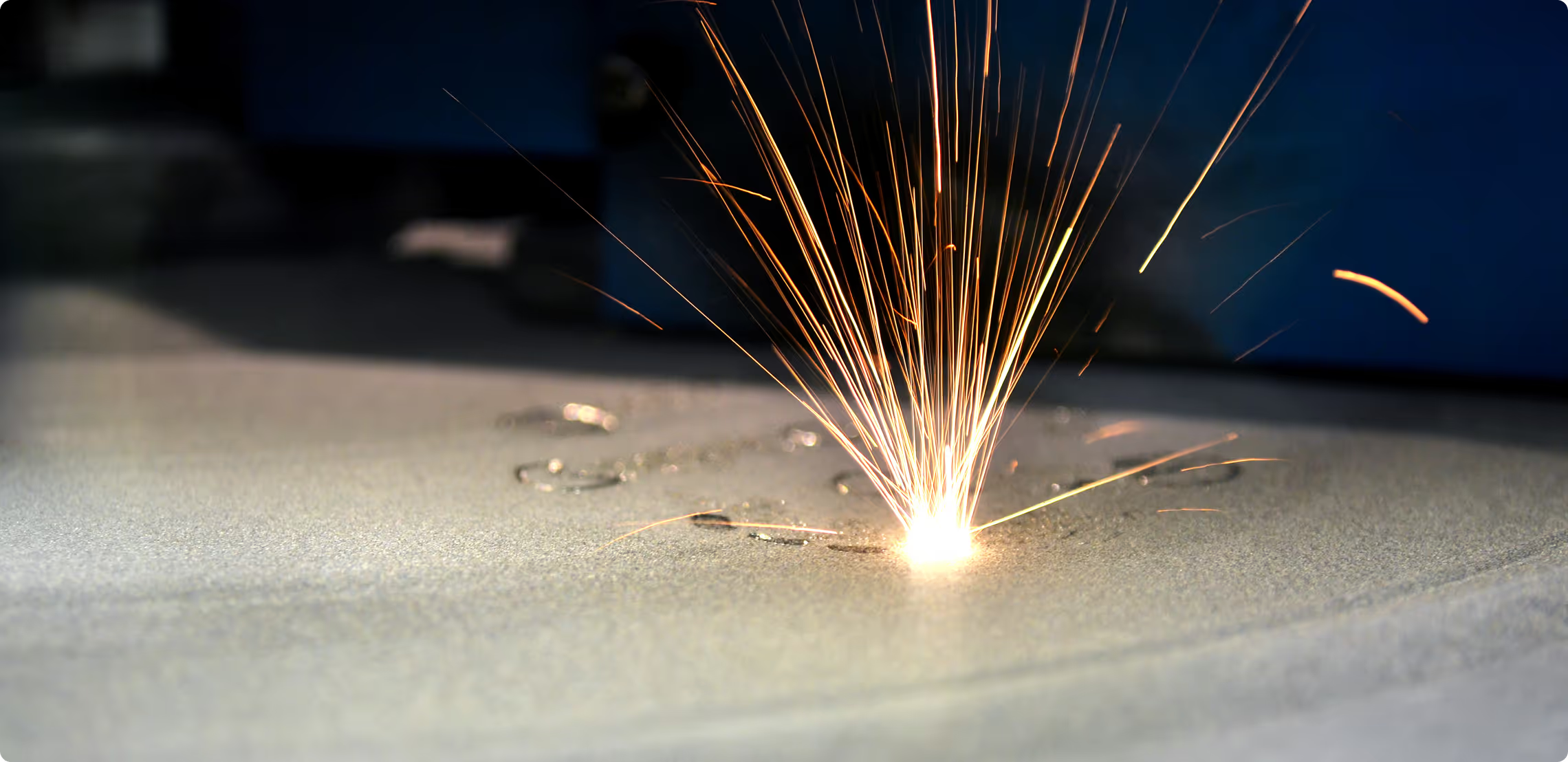

How Metal 3D Printing Works

DMLS (Direct Metal Laser Sintering) uses a high-powered fiber laser to selectively fuse fine metal powder particles layer by layer in an inert atmosphere. The result is fully dense metal parts with properties matching or exceeding traditionally manufactured metals.

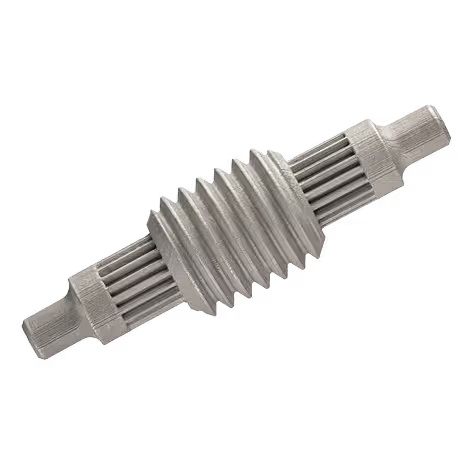

This process enables complex internal geometries, topology-optimized structures, and part consolidation impossible with CNC machining or casting. From aerospace brackets to medical implants, metal 3D printing delivers design freedom with production-grade strength.

Key Advantages

- High Density: Typically >99% density. Properties can approach wrought with the right material, orientation, and optional post-processing.

- Complex Geometries: Internal channels, lattices, and consolidated assemblies

- Aerospace-Grade Alloys: Titanium, Inconel, and certified materials

- No Tooling Required: Direct from CAD to metal part

- Weight Reduction: Topology optimization for lightweighting

Material & Geometry Review

We analyze your part for optimal alloy selection and build orientation.

Laser Sintering

High-powered laser fuses metal powder layer by layer in inert atmosphere.

Optional Heat Treatment

Stress relief and property optimization are available as an add-on when required by the application.

Post-Processing & QC

Support removal, cleaning, optional surface finishing, and dimensional verification.

Available Materials

Industrial-grade metal powders for demanding applications. Each alloy is selected for specific performance characteristics.

Stainless Steel 316L

Most PopularExcellent corrosion resistance and mechanical strength. Low-carbon austenitic stainless ideal for marine, medical, and food processing applications.

Stainless Steel 17-4 PH

High StrengthPrecipitation-hardening stainless with high strength and good corrosion resistance. Ideal for mechanical components and aerospace applications.

Aluminum AlSi10Mg

LightweightHigh strength-to-weight ratio with excellent thermal conductivity. Ideal for aerospace, automotive, and heat management applications.

Titanium Ti-6Al-4V (Ti64)

Aerospace GradeThe "workhorse" titanium alloy. Exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility for aerospace and medical implants.

Inconel 625

SuperalloyNickel-based superalloy with exceptional high-temperature strength and corrosion resistance. For turbine components and extreme environments.

Maraging Steel

Tool SteelUltra-high-strength low-carbon steel. Age-hardenable to extreme hardness. Ideal for tooling, dies, and high-stress mechanical components.

Metal Printing Design Guidelines

Design considerations for successful metal additive manufacturing. Our team reviews every file for manufacturability.

Build Volume

Up to 400×400×300mm

Varies by material. Titanium limited to 150×150×200mm due to reactive nature.

Tolerance

±0.2mm to ±0.5mm

As-printed guidance. Depends on size and geometry: <100mm: ±0.2mm, <200mm: ±0.3mm, <300mm: ±0.4mm.

Layer Height

0.02mm – 0.06mm

Fine layers ensure fully dense parts. Optimal thickness selected per alloy.

Minimum Wall Thickness

0.5mm – 1.0mm

Depends on geometry and material. Thinner walls increase risk of distortion; self-supporting walls typically need ~1mm+.

Overhang Angle

>45° from horizontal

Shallower overhangs require support structures, which leave marks when removed.

Surface Finish

Ra ~10–30 μm as-printed

Varies by material, orientation, and supports. Optional surface finishing can be quoted for appearance or functional surfaces.

What Metal 3D Printing Is Best For

Aerospace Components

Lightweight brackets, turbine blades, ducting, and structural components with complex internal cooling channels.

Medical Implants

Patient-specific implants, surgical guides, and medical instruments in biocompatible titanium and stainless steel.

Tooling & Molds

Conformal cooling channels in injection molds, dies, and manufacturing fixtures for improved cycle times.

Heat Exchangers

Complex internal geometries for maximized surface area and optimized thermal performance.

Consolidated Assemblies

Combine multiple parts into single prints—reduce assembly time, weight, and potential failure points.

Motorsport & Performance

Lightweight structural parts, turbocharger housings, and custom components for racing applications.

Metal Post-Processing

Choose add-ons to enhance performance and appearance based on your application.

Support Removal & Cleaning

Standard cleanup and support removal as required to deliver usable parts.

IncludedHeat Treatment

Stress relief / property optimization when required by the application or material. Quoted per project.

Add-OnSurface Finishing

Optional finishing for aesthetics or functional surfaces (varies by material and geometry).

Add-OnAnodizing (Aluminum)

Protective oxide layer for enhanced corrosion resistance and appearance. Color options available.

Add-OnMetal 3D Printing Questions

How does metal 3D printing compare to CNC machining?

Metal 3D printing (DMLS/LPBF) shines for complex geometries—internal channels, lattices, lightweighting, and shapes that would be difficult or impossible to machine. CNC machining is often the better choice for simple geometries, very tight tolerances across many features, or high volumes. If you're unsure which process fits your part, we can help you choose the most practical path.

Are metal 3D printed parts as strong as machined parts?

They can be—depending on the alloy, build orientation, and post-processing (stress relief, heat treatment, and sometimes HIP). Metal AM parts are typically printed to high density (often ~99%+), and with the right process they can achieve mechanical properties comparable to wrought or cast materials. If you have a specific strength, fatigue, or certification requirement, we’ll review it and propose the right material and process path.

Why is metal 3D printing more expensive?

Costs include metal powder, specialized equipment and inert gas handling, build setup, support removal, and post-processing/inspection. Optional add-ons like heat treatment and surface finishing can add cost and lead time. For some geometries, metal AM can reduce total manufacturing steps versus complex multi-operation machining—but it’s not always the lowest-cost option for simple parts.

What's the typical lead time for metal parts?

10–30 days depending on complexity, material, and post-processing requirements. This typically includes file review, printing, support removal/cleaning, and quality inspection. Optional add-ons (heat treatment, surface finishing) can add time. Rush options may be available for urgent projects.

Can you achieve tight tolerances on metal parts?

Typical as-printed tolerances are in the ±0.2mm to ±0.5mm range depending on geometry and size. For press fits, precision bores, threads, and sealing/mating surfaces, plan your design so those features can be finished as secondary operations by your machine shop (or choose an alternate manufacturing method). We’ll flag tolerance-critical features during file review.

Do you provide material certification?

Yes. We can provide material certifications, dimensional inspection reports, and test samples upon request. For aerospace and medical applications requiring full traceability, we work with certified partners and documented processes.

Ready for Metal 3D Printing?

Send us your file for a detailed quote. Fully dense metal parts with design freedom and production-grade properties.