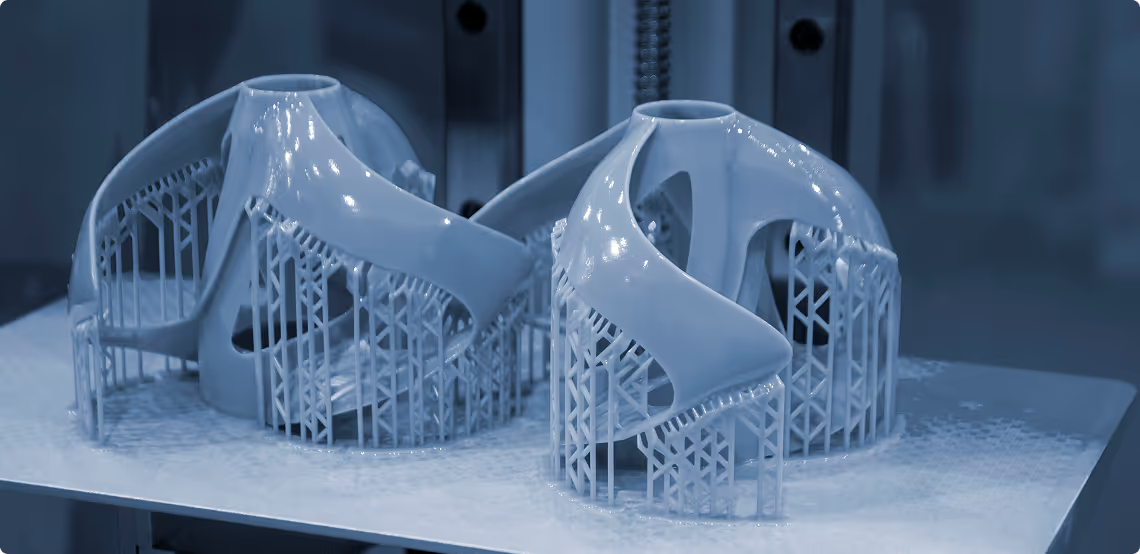

SLA Resin 3D Printing

Stereolithography

Ultra-high resolution printing with glass-smooth surface finishes. SLA delivers the finest detail and best surface quality available in 3D printing—perfect for prototypes, molds, jewelry, and visual models.

How SLA 3D Printing Works

SLA (Stereolithography) uses a UV laser to cure liquid photopolymer resin layer by layer with extreme precision. Each layer is just 25–100 microns thick, resulting in parts with incredibly fine detail and smooth surfaces.

This process makes SLA the gold standard for high-detail applications like jewelry masters, dental models, presentation prototypes, and precision molds. With specialty resins available for flexibility, high-temperature resistance, and castability, SLA handles demanding applications other technologies can't match.

Key Advantages

- Highest Detail: Resolution down to 25 microns for razor-sharp features

- Smooth Surfaces: Near-injection-molded finish with minimal post-processing

- Tight Tolerances: ±0.15mm accuracy for precision assemblies

- Specialty Resins: Clear, flexible, high-temp, castable, and biocompatible options

- Isotropic Properties: Consistent strength in all directions

Resin Selection

Choose the right resin for your application—standard, tough, clear, flexible, or specialty.

File Preparation

We optimize orientation and supports for best surface quality and dimensional accuracy.

High-Resolution Print

UV laser cures resin layer by layer at resolutions as fine as 25 microns.

Wash, Cure & Finish

Parts are washed, UV cured, and supports removed with minimal scarring.

SLA Resins & Properties

We run Formlabs printers with an extensive resin library. Each resin is engineered for specific properties—from rigid strength to rubber-like flexibility.

Standard Resin

Most PopularCrisp edges, high resolution, and smooth finish. Ideal for visual validation, fit testing, concept models, and design iteration.

Tough Resin

High StrengthSimulates ABS with high impact resistance and stiffness. Perfect for functional prototypes, snap-fits, and mechanical testing.

Clear Resin

TransparentWater-clear transparency when polished. Ideal for light pipes, lenses, fluid flow visualization, and optical prototypes.

Flexible / Elastic Resin

Rubber-LikeSoft, pliable parts that bend and compress. Great for gaskets, grips, wearables, and soft-touch components.

High Temp Resin

SpecialtyHeat Deflection: 238°C

Industry-leading thermal stability for molds, hot gas testing, and heat-resistant fixtures. Maintains accuracy at extreme temperatures.

Castable Wax Resin

JewelryWax-filled resin for investment casting. Burns out cleanly with zero ash residue. Ideal for jewelry, dental, and precision metal casting.

Durable Resin

Wear ResistantSimulates polypropylene with high impact strength and low friction. Perfect for living hinges, snap-fits, and wear surfaces.

ESD Resin

SpecialtyStatic-dissipative material for electronics manufacturing. Protects sensitive components from electrostatic discharge.

We can print almost any resin in the Formlabs library. Need something specific?

Request Custom ResinSLA Design Guidelines

Follow these guidelines for optimal results. Our team reviews every file and suggests improvements as needed.

Build Volume

145×145×185mm

In-house Formlabs capacity. Partner network offers up to 1800×900×600mm for larger parts.

Tolerance

±0.15mm or ±0.3%

Whichever is greater. Castable and flexible materialsmay have more variation.

Layer Height

0.025mm – 0.1mm

Standard 0.05mm. Extra-high definition available at 0.025mm for finest detail.

Minimum Wall Thickness

0.2mm

Thinner walls possible but may flex. Unsupported walls need extra thickness.

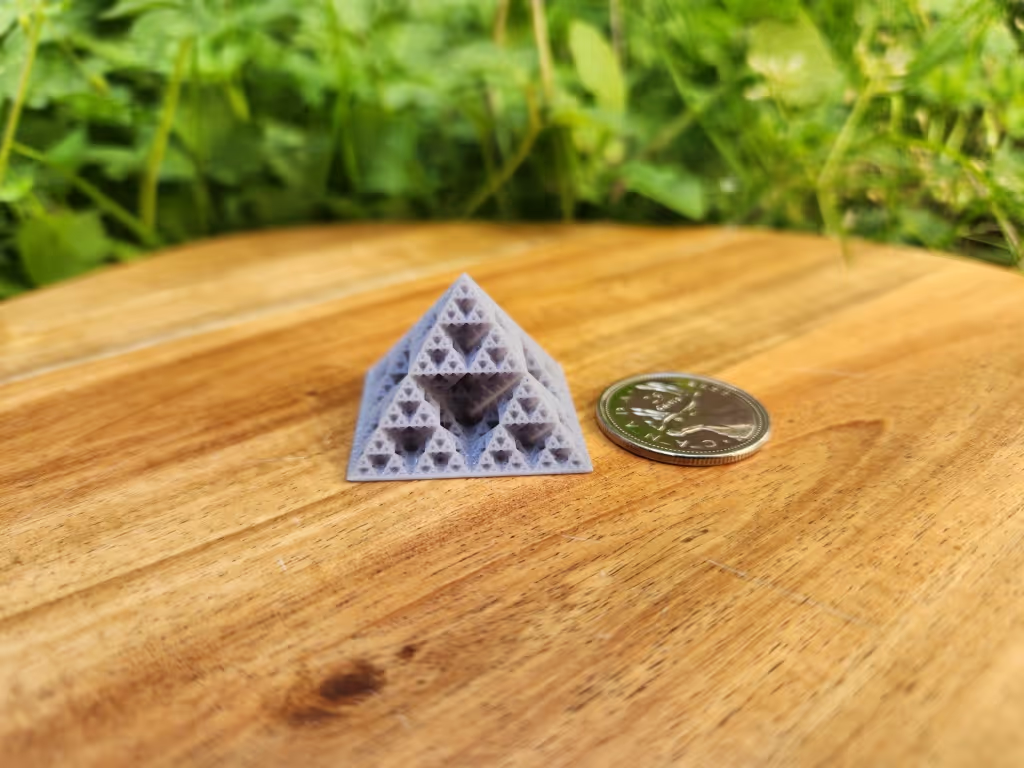

Minimum Detail

0.1mm

Details less than 0.1 mm thick and 0.1 mm tall may not be visible on the completed print.

Surface Finish

Near injection-molded

Smooth, uniform surface. Very fine layer lines may be visible on shallow angles.

What SLA Is Best For

Visual Prototypes

Presentation-quality models with smooth surfaces for client demos, investor pitches, and design reviews.

Jewelry & Casting

Intricate jewelry masters and castable patterns with exceptional surface quality for investment casting.

Molds & Tooling

High-temperature molds for thermoforming, silicone casting, and short-run injection molding.

Dental & Medical

Surgical guides, dental models, anatomical models, and biocompatible devices with USP Class VI certification.

Optical Components

Clear lenses, light guides, fluid flow visualization, and transparent housings with glass-like clarity.

Miniatures & Figurines

Highly detailed gaming miniatures, artistic sculptures, and collectible figurines with crisp features.

SLA 3D Printing Questions

How does SLA compare to FDM and SLS?

SLA delivers very high resolution and smooth surfaces—ideal for visual prototypes and detailed parts. FDM is more cost-effective for functional parts with visible layer lines. SLS produces durable nylon parts without supports but has a lightly textured finish. Choose SLA when detail and surface quality matter most.

What factors affect SLA printing cost?

Cost depends on part size, print time, resin type, and post-processing. SLA builds parts upward from a resin tank, so taller parts take longer. Specialty resins (clear, high-temp, castable) cost more than standard. We provide transparent quotes upfront.

Which SLA resin should I use?

Standard Grey for most applications—good all-around. Tough for functional testing. Clear for optical transparency. Flexible for rubber-like parts. High Temp for molds and heat exposure. We'll recommend the best resin for your use case.

How accurate and smooth are SLA parts?

SLA is known for high resolution and very smooth surfaces compared to FDM. Layer heights are commonly in the 25–100µm range, which helps capture fine details. Typical dimensional accuracy depends on geometry, resin, and post-cure, but many parts can be held to ±0.15mm or ±0.3% (whichever is greater) with proper design. If you have a critical tolerance or cosmetic requirement, we'll review it and recommend the best approach (including post-processing if needed).

How quickly can you deliver SLA parts?

Most SLA orders ship within 1–4 business days depending on size and resin. We offer local pickup in Victoria and Canada-wide tracked shipping. Rush options may be available for urgent projects.

What's the maximum part size for SLA?

In-house we print up to 145×145×185mm. For larger parts, we can split and bond sections, or recommend a better-fit process (often large-format FDM) depending on strength, finish, and budget.

Ready for High-Resolution SLA Printing?

Upload your file, choose your resin, and get an instant quote. The finest detail and smoothest surfaces in 3D printing.