Professional 3D Printing Services

Whether you're after 1 or 10,000 parts, we've got you covered. We run industrial 3D printers in Victoria, BC to get your parts made fast, in Canada.

Choose the Right 3D Printing Technology

Each technology excels in different applications. Select based on your requirements for detail, strength, material properties, and budget.

FDM 3D Printing

Fused Deposition Modeling

Cost-effective thermoplastic parts for functional prototypes, enclosures, brackets, and tooling. Fast turnaround with 15+ material options.

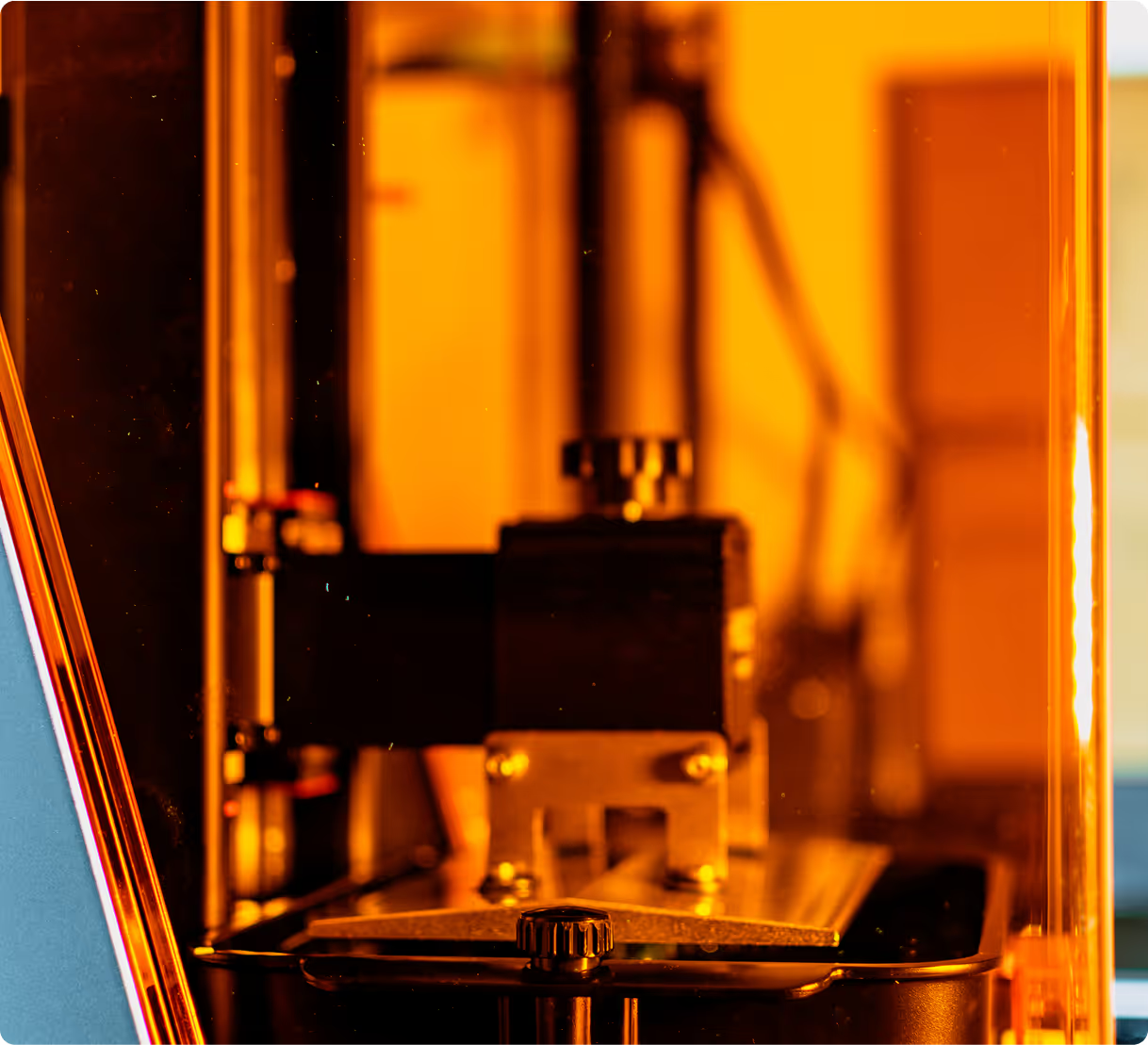

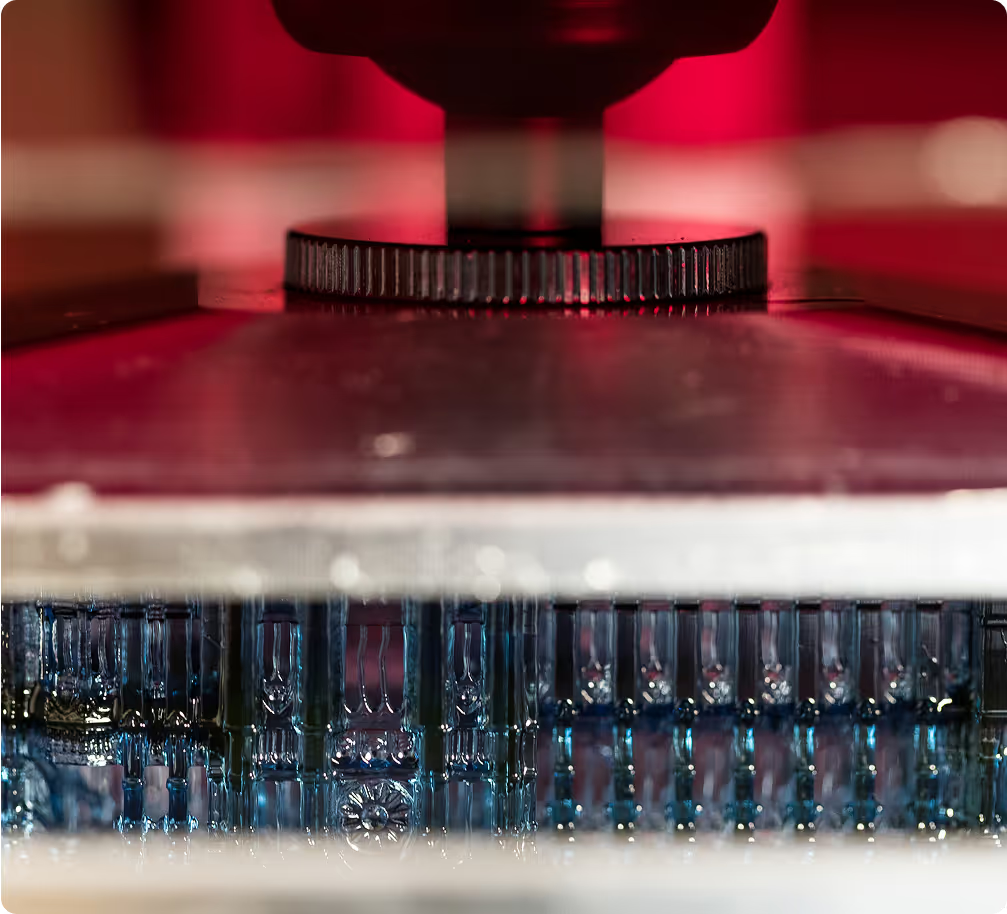

SLA Resin Printing

Stereolithography

Ultra-high resolution with smooth surfaces. Perfect for detailed prototypes, molds, jewelry masters, and presentation models.

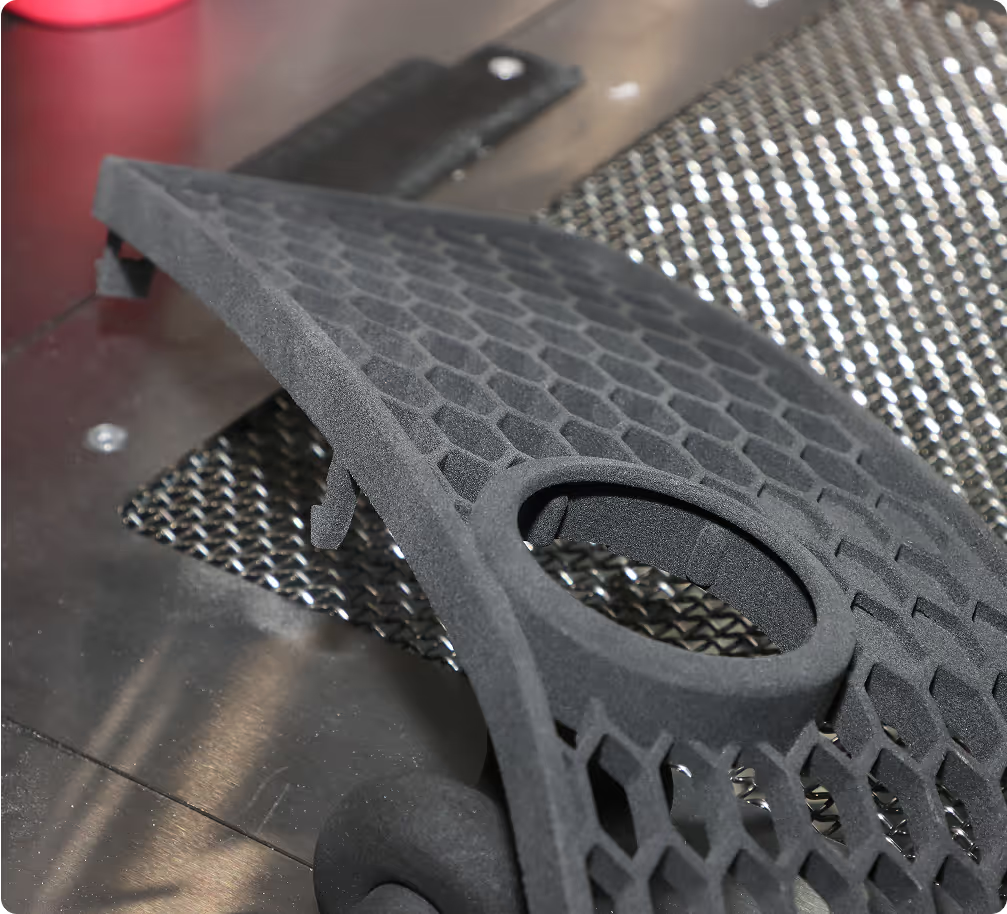

SLS 3D Printing

Selective Laser Sintering

Durable nylon parts without support structures. Ideal for complex geometries, end-use components, and demanding applications.

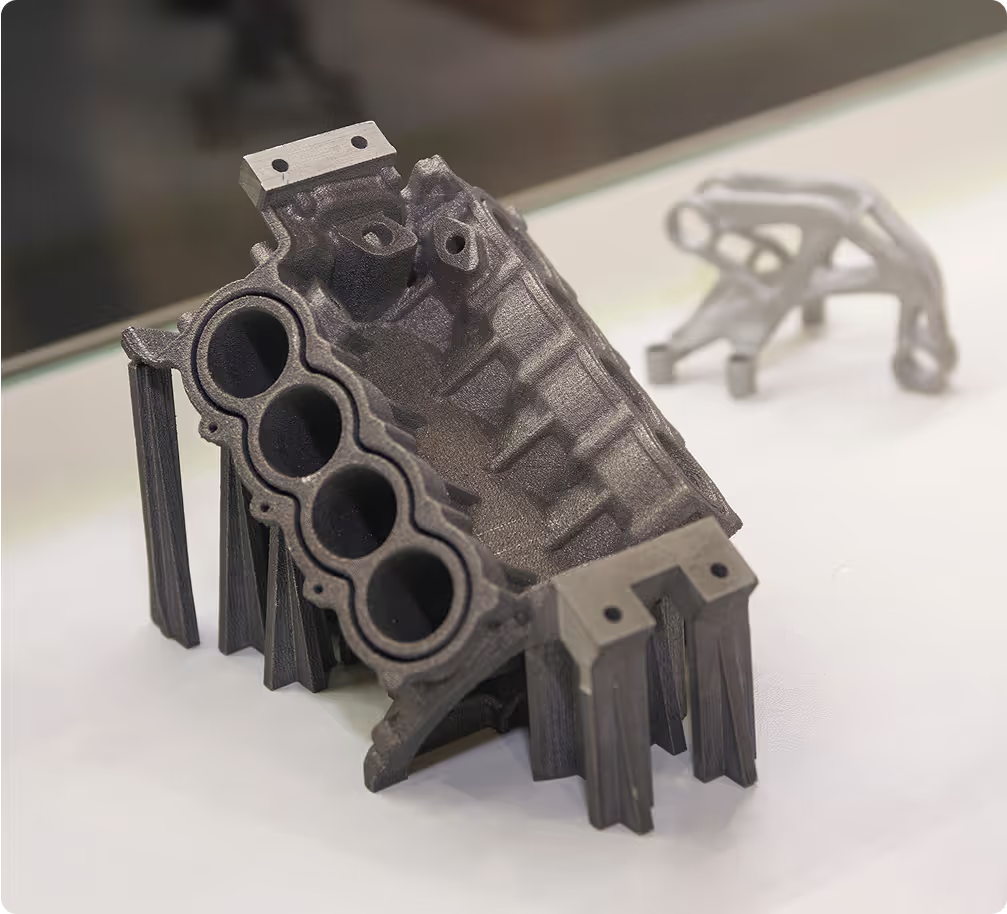

Metal 3D Printing

DMLS / Binder Jetting

Fully dense metal parts in stainless steel, aluminum, titanium, and Inconel. For when strength and precision are critical.

Technology Comparison at a Glance

| Property | FDM | SLA | SLS | Metal (DMLS) |

|---|---|---|---|---|

| Surface Finish | Visible layers | Ultra-smooth | Fine texture | Matte (post-processed) |

| Strength | Good | Moderate | Excellent | Superior |

| Detail Resolution | Moderate | Excellent | Good | Good |

| Support Structures | Required | Required | None needed | Required |

| Cost | $ | $$ | $$$ | $$$$ |

| Best Volume | 1–500+ units | 1–100 units | 10–1000+ units | 10–100 units |

From File to Finished Part

We've streamlined the entire process so you can focus on what matters—your project.

Upload Your File

Upload your CAD file through our instant quote system. We accept STL, STEP, OBJ, and 3MF formats.

Configure & Quote

Select your technology, material, quantity, and finish. Get real-time pricing and lead times instantly.

We Print & QC

Our team reviews your file and produces your parts using calibrated, industrial-grade equipment.

Fast Delivery

Parts are quality-checked and shipped across Canada. Local Victoria pickup available same day.

Frequently Asked Questions

Which 3D printing technology should I choose?

It depends on your part’s requirements. FDM is a great value for functional parts and large prototypes. SLA is best when fine detail and smooth surfaces matter. SLS produces durable nylon parts without support structures (and with more uniform strength than FDM). Metal is for high-strength, high-temperature, or complex metal parts—often combined with machining for critical features. Not sure? We can recommend the best process based on your file and use case.

How fast can you deliver parts?

Typical lead times are 1–4 business days for FDM and SLA, 5–10 business days for SLS, and 10–30 business days for metal—depending on part size, quantity, and finishing. We offer local pickup in Victoria and expedited shipping across Canada when available.

What file formats do you accept?

We accept STEP (.step/.stp, preferred for engineering parts), STL, 3MF, and OBJ. If you’re exporting a mesh (STL/3MF/OBJ), make sure it’s watertight/manifold and correctly scaled to mm (make sure to indicate when a file has custom scaling). We’ll review every file and reach out if anything needs adjustment.

What are the quickest ways to lower my project cost?

Add more parts to your order—we offer volume discounts. Increase the layer height if surface finish isn't critical. Let us recommend the most cost-effective technology and material for your application.

Can you handle CAD design if I only have a sketch?

Absolutely. Our in-house design team can turn your sketch, photo, or physical object into a production-ready 3D model. We also offer 3D scanning services for reverse engineering existing parts.

How large can you print?

Typical in-house max build sizes are: FDM up to 1m³, SLA up to 145×145×185mm, and SLS up to 155×155×295mm. For larger parts, we can split and assemble them cleanly—and for very large FDM prints we can source partner production (up to 2100×700×900mm, project dependent). Metal build sizes vary by alloy and system; ask us if you have a specific envelope requirement.

Ready to Start Your Project?

Upload your file, pick a material, and get your parts printed. No back-and-forth emails. No guesswork.