Events

Events

The Problem

An avid hummingbird photographer wanted to immortalize one of their most beautiful shots by transforming it into a piece of fine jewelry. The client had a stunning 2D image but needed a way to translate its intricate details into a physical 3D form suitable for the precise process of investment casting. Their goal was to create cast gold pins of the specific hummingbird from their photograph, capturing its unique beauty in a permanent three-dimensional form.

Our Solution

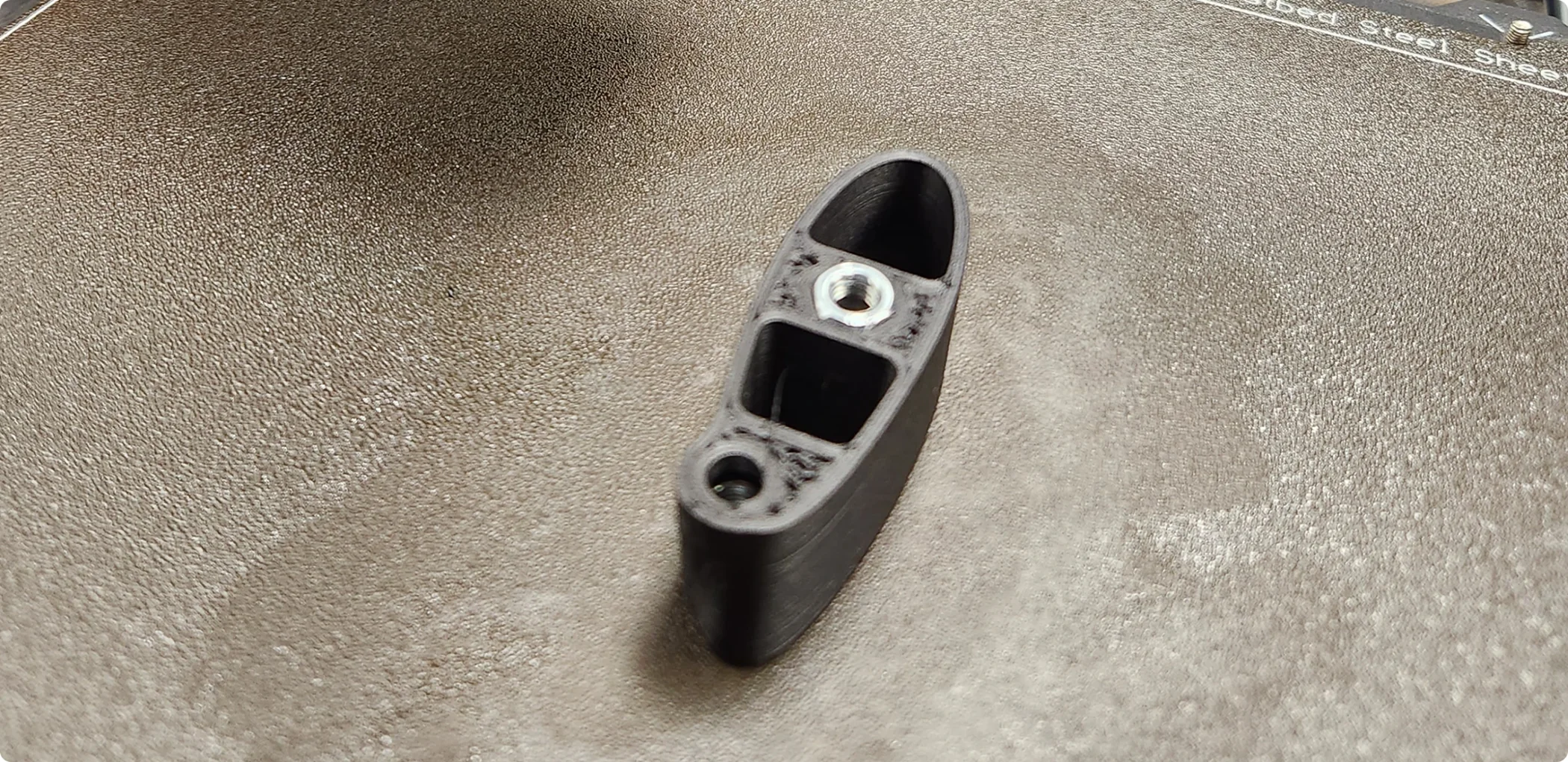

The process began by modeling the hummingbird in Blender, using the client's photograph as the primary reference to ensure artistic and anatomical accuracy. This phase presented unique challenges: the beak was extremely thin and fragile, requiring careful digital reinforcement, while the body needed to be hollowed out to optimize material use for the final casting. We worked closely with the photographer through numerous design revisions, printing physical prototypes in standard resin so they could hold and approve the design before finalizing it. Once approved, we printed the final blanks using Formlabs Castable Wax 40, a specialized resin designed for a clean burnout during the investment casting process.

The Results

With the high-fidelity wax models in hand, the client successfully cast the hummingbird pins in silver and finished them with beautiful gold plating at a local jeweler. This project highlights our ability to manage a highly detailed artistic process, transforming a client's 2D concept into a tangible, high-fidelity model ready for professional jewelry manufacturing.