High Performance Cycling Components

A competitive cyclist needed a custom handlebar setup for optimal ergonomics. We printed prototypes in carbon-fiber nylon, tested on real rides, then machined the final part in aluminum.

View Case StudyWhen a local collector needed interior trim for his grandfather's 1967 Mustang, we scanned the broken originals and printed stronger replacements in a week. See how restorers and shops across BC use 3D printing to find parts that don't exist anymore.

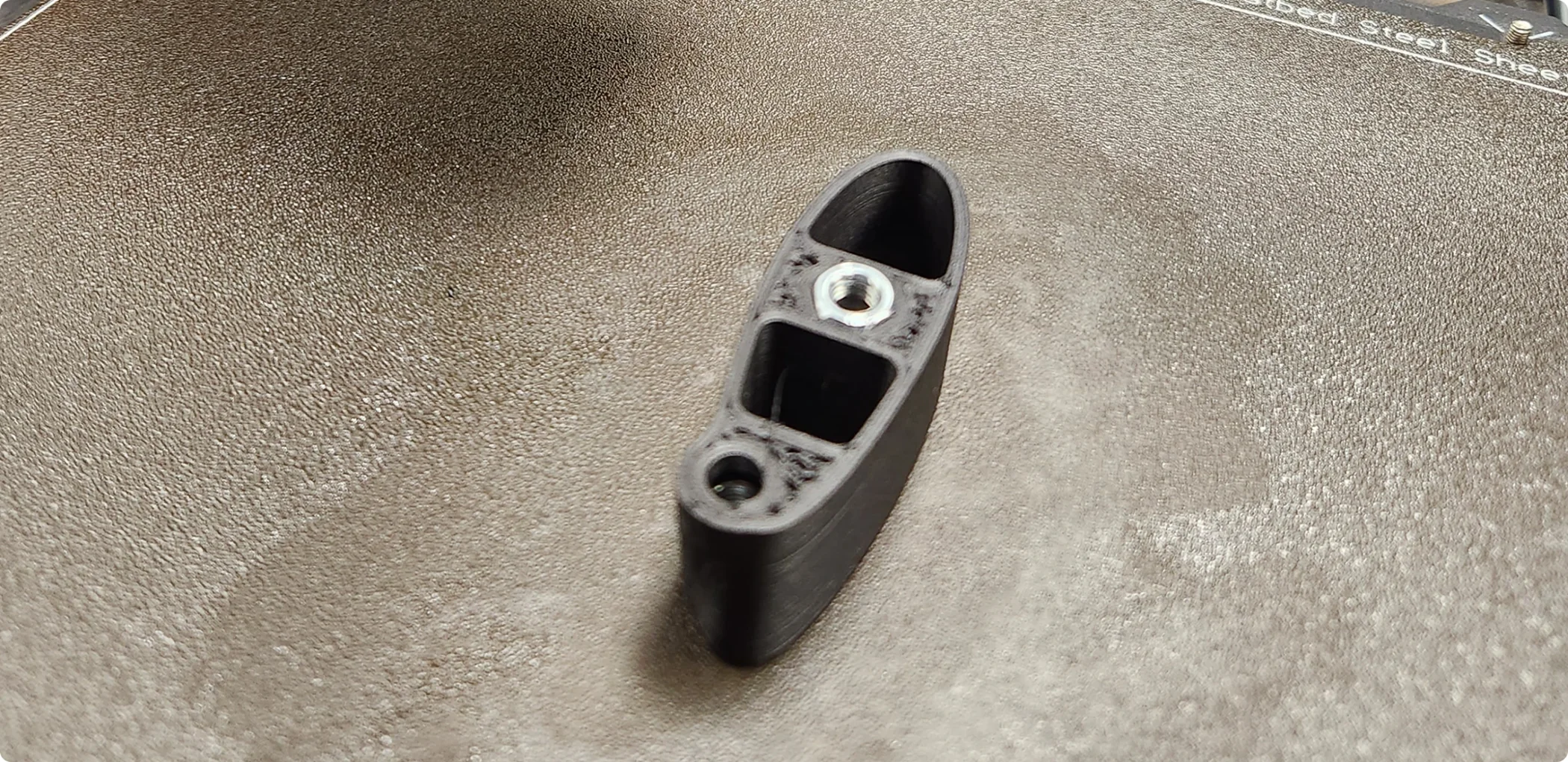

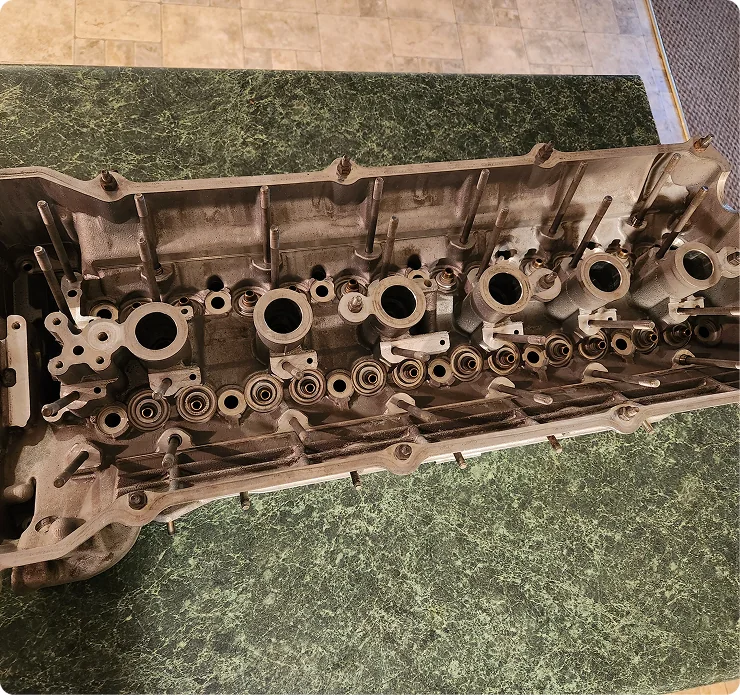

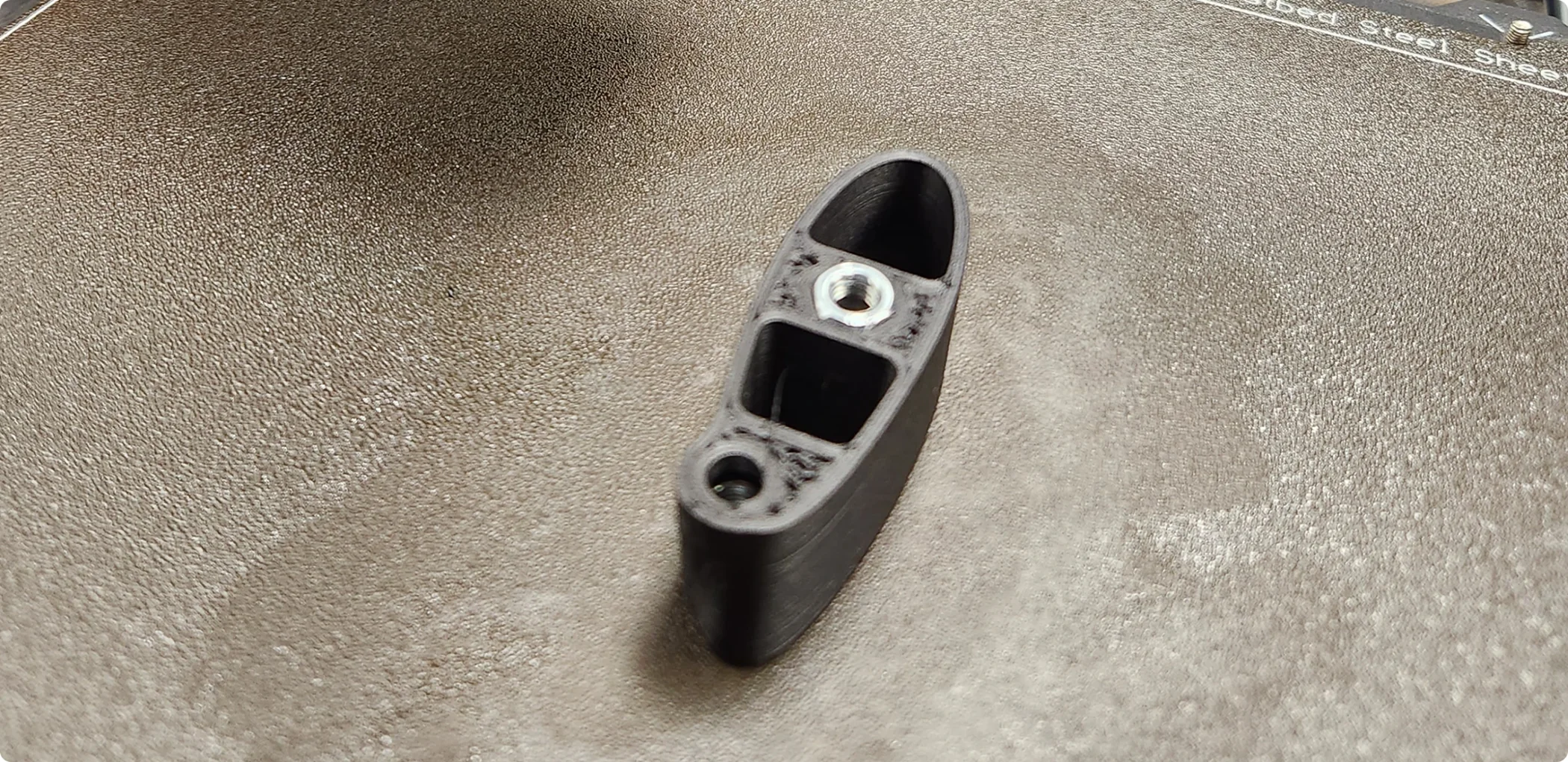

A local enthusiast restoring his grandfather's 1967 Ford Mustang hit a standstill. Several interior trim pieces and a brittle air-intake manifold were broken beyond repair. After months of searching, he discovered the parts were long out of production. The few used pieces on the market were either in poor condition or priced at hundreds of dollars each.

We 3D scanned the broken originals to capture exact geometry, digitally repaired the damage, and reinforced known weak points. The parts were printed in ASA, a UV-stable material that handles under-hood heat and won't degrade like the 50-year-old originals did.

Perfect-fit replacement parts that look original and will outlast the originals. The collector has the digital files archived for future reprints if ever needed. The restoration was completed weeks ahead of the original timeline.

From custom cycling components to vintage car parts, see how we help people solve transportation challenges.

A competitive cyclist needed a custom handlebar setup for optimal ergonomics. We printed prototypes in carbon-fiber nylon, tested on real rides, then machined the final part in aluminum.

View Case Study

Learn how 3D scanning captures irreplaceable geometry from classic vehicles, even from broken or worn parts, and how we turn those scans into functional replacements.

Read the StoryWorking on a restoration or custom build? Have a part that doesn't exist anymore? We'd love to hear about it.

Get In TouchTraditional parts sourcing vs. Morin 3D. See why car enthusiasts and shops are making the switch.

| Traditional Parts Sourcing | Morin 3D |

|---|---|

| Months searching swap meets and eBay | ✓ Parts in 1 week or less |

| NOS parts are expensive and disappearing | ✓ Scan once, print forever |

| Aftermarket reproductions often don't fit | ✓ Exact geometry from your original |

| Donor car parts may be just as worn | ✓ Brand new, stronger than original |

| Limited to what someone else made | ✓ Custom modifications possible |

| One part at a time, hope it fits | ✓ Print multiples, keep spares |

Real parts for real vehicles, from classic restorations to daily drivers.

The right material depends on where the part lives and what it does.

Bring us the original (even if it's broken), a photo, or just a description. We'll figure out if 3D printing is the right fit and get it made.