There's something irreplaceable about a vintage car. Maybe it's your grandfather's '67 Mustang, a barn-find Porsche 356, or a classic Mercedes Gullwing that's been in the family for generations. These machines represent more than transportation; they're rolling history, mechanical art, and deeply personal connections to the past.

But try finding parts for a 50-year-old car. The manufacturer stopped making them decades ago. Aftermarket suppliers may have never tooled them in the first place. And the one on eBay from Hungary? It's the wrong year, wrong side, and definitely not returning.

This is where 3D scanning changes everything for automotive restoration.

The Problem with Classic Car Parts

Classic car enthusiasts face a common dilemma: the parts that break or wear out are often the same parts that nobody makes anymore. Interior trim, dashboard components, body panels, weatherstripping, emblems: the list goes on.

Traditional solutions have serious limitations:

- NOS (New Old Stock): Rare, expensive, and when it's gone, it's gone forever

- Aftermarket reproductions: Variable quality, often don't fit properly

- Donor cars: Destroying one car to save another, and the donor parts may be just as worn

- Custom fabrication: Expensive and requires finding a craftsman who understands the car

Enter 3D Scanning

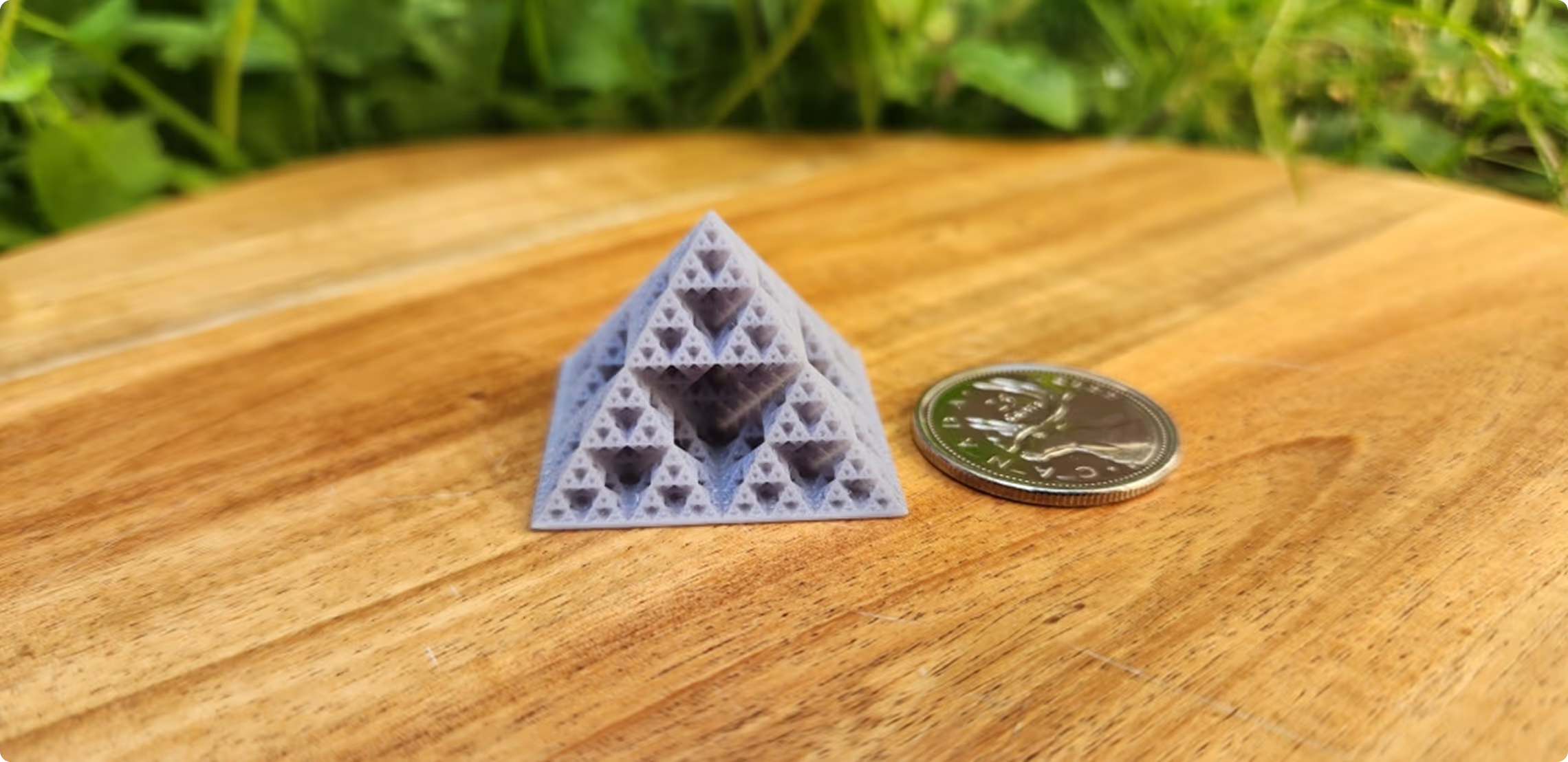

3D scanning captures the exact geometry of an existing part, down to fractions of a millimeter. Even if the original is damaged, worn, or incomplete, scanning creates a digital foundation to work from.

What We Can Capture

- Exterior trim: Badges, emblems, grilles, mirror housings

- Interior components: Knobs, handles, bezels, vent surrounds

- Mechanical parts: Brackets, spacers, housings, adapters

- Complex surfaces: Dashboard contours, body panel sections

The Scanning Process

Modern handheld 3D scanners capture surface geometry using structured light or laser triangulation. For automotive work, we typically use structured light scanning, which projects a pattern onto the surface and calculates 3D coordinates from how that pattern deforms.

Step 1: Preparation. We clean the part and apply reference markers if needed. High-gloss or transparent surfaces may require a light dusting of scanning spray.

Step 2: Scanning. We move the scanner around the part, capturing millions of surface points from multiple angles. Software stitches these captures together in real-time.

Step 3: Processing. The raw scan data becomes a watertight 3D mesh or CAD-ready surface. We can fill holes, smooth noise, and prepare the model for whatever comes next.

Step 4: Manufacturing. Depending on the application, we can 3D print the part directly, create molds for casting, or export files for CNC machining.

Real Example: 1967 Mustang Interior Parts

A local collector brought us a '67 Mustang with several broken interior trim pieces. The originals were brittle from decades of heat cycles and UV exposure. Aftermarket replacements existed, but the fit and finish were noticeably inferior.

We scanned the broken originals, digitally repaired the damage in CAD, and printed prototypes for test fitting. Once verified, we printed final parts in ASA, a UV-stable material that won't degrade like the originals did.

The result? Parts that look original, fit perfectly, and will outlast the originals. The collector has the digital files archived for future reprints if ever needed.

"I'd spent two years searching for these parts. Morin 3D scanned my broken pieces and had working replacements in less than a week. They fit better than the NOS parts I'd seen at swap meets."

– Victoria classic car collector

When Scanning Makes Sense

3D scanning isn't always the answer. Here's when it provides the most value:

- Unobtainable parts: When you can't buy a replacement at any price

- Poor-fit aftermarket: When reproductions exist but don't fit properly

- Custom modifications: Adapting modern components to vintage mounting points

- Preservation: Archiving irreplaceable geometry before it's lost

- Multiple copies: When you need several identical parts

Materials for Automotive Applications

The right material depends on where the part lives and what it does:

- ASA: UV-stable, ideal for exterior trim and anything exposed to sunlight

- PETG: Good chemical resistance, works well for under-hood components

- PA-CF (Carbon Fiber Nylon): High strength-to-weight for structural applications

- Flexible TPU: Gaskets, grommets, and vibration dampening

- SLA Resins: High detail for emblems and decorative pieces

Beyond Plastic: Paths to Metal Parts

Sometimes a plastic replacement won't cut it. For metal parts, 3D scanning still provides the foundation:

- Investment casting: We print patterns in castable wax resin, which foundries can cast in bronze, aluminum, or steel

- CNC machining: Export scan data as CAD files for traditional machining

- Metal 3D printing: For complex geometries in stainless steel, aluminum, or titanium

Get Started

If you're working on a restoration and can't find the parts you need, we'd love to help. Bring us the original (even if it's broken), tell us about the application, and we'll figure out the best approach together.

Learn about our 3D scanning services or contact us to discuss your project.