When a contractor came to us needing custom concrete forms for pool stools, they'd already hit a wall with traditional methods. The carpenter had quoted a week to build wood forms. If the dimensions changed, they'd be starting from scratch.

We printed their forms in 48 hours. When the client decided mid-project to resize from 15" to 13" diameter, we adjusted the CAD file and had new forms ready the next day. No wasted wood. No delays. No frustrated carpenters.

Why 3D Printed Concrete Forms Make Sense

Traditional formwork works great until it doesn't. Complex curves, custom dimensions, and tight timelines expose the limitations of wood and metal forms. Here's where 3D printing shines:

- Speed: From CAD to finished form in 24-72 hours, not days or weeks

- Flexibility: Design changes take minutes instead of hours of rework

- Geometry: Complex curves and organic shapes print as easily as boxes

- Repeatability: Need 50 identical forms? We print them identically

- Cost: For small runs and prototypes, often cheaper than custom carpentry

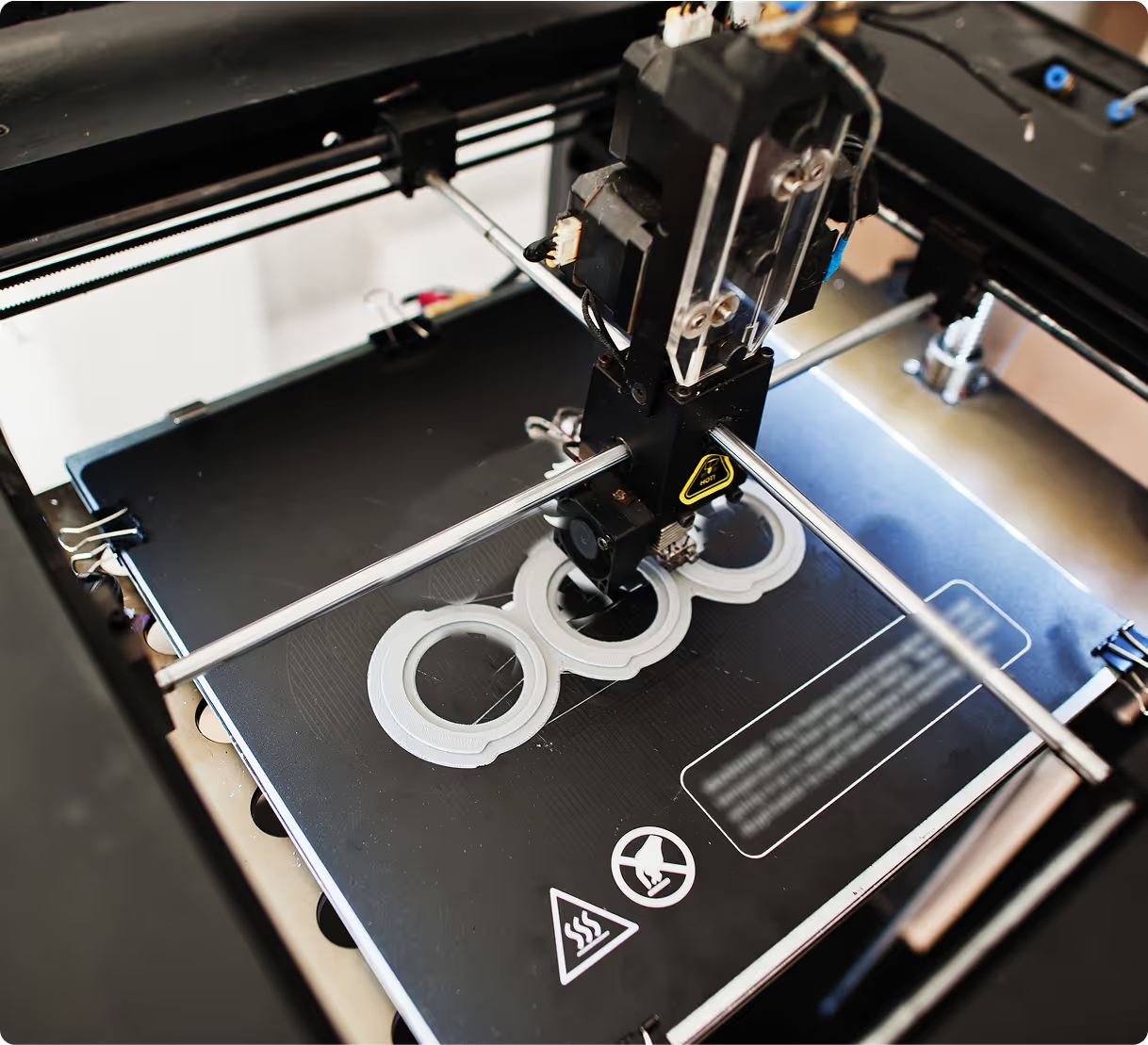

The Technology Behind It

We use Large Format Additive Manufacturing (LFAM) with industrial FDM printers capable of producing forms up to several feet in any dimension. The key is material selection:

Best Materials for Concrete Forms

- PETG: Our go-to for most applications. Strong, weather-resistant, and releases cleanly from cured concrete with mold release.

- ABS: Great for forms that need to be reused many times. More rigid than PETG.

- ASA: When forms will be exposed to UV and weather for extended periods.

Real Project: Pool Stool Forms

The pool stool project perfectly illustrates the advantages. The contractor needed cylindrical forms with a specific taper: easy to describe, tedious to build in wood. Traditional approach:

- Carpenter measures and cuts segments

- Assembles form with hardware

- Tests fit with initial pour

- Adjusts (or starts over) if dimensions are wrong

With 3D printing, we modeled the exact geometry in CAD, printed a test form overnight, and the contractor verified the fit before committing to the full set. When the client requested the diameter change, we adjusted one parameter and reprinted.

"I couldn't believe how fast they turned it around. And when we had to change the size, I expected to lose a week. They had new forms ready the next morning."

– Victoria-area Contractor

When Does 3D Printing Beat Traditional Forms?

3D printed forms aren't always the answer. Here's when they make the most sense:

- Custom one-off shapes where tooling up traditional forms isn't economical

- Prototype pours where you're still dialing in dimensions

- Complex geometry that would require expensive CNC work in wood or foam

- Rush jobs where waiting for fabrication would delay the project

- Small production runs (2-50 identical forms)

For large-scale production with simple geometry, traditional formwork usually wins on cost. But for the scenarios above, 3D printing delivers speed and flexibility that traditional methods can't match.

Getting Started

If you've got a concrete project with custom form requirements, we'd love to hear about it. Send us a sketch, describe what you need, or share existing drawings; we'll tell you whether 3D printing makes sense and provide a quote within hours.

Contact us or upload your files to get started.