If you've ever picked up an FDM-printed part and run your finger across those telltale layer lines, you know the feeling. The part works fine, but it looks 3D printed. For functional prototypes hidden inside an enclosure, that's rarely a problem. But for client presentations, consumer products, or parts that need precision fits, those visible layers matter.

SLA (stereolithography) resin printing solves this. The technology produces surfaces so smooth they can look injection-molded straight off the printer. Here's why.

The Science of Smooth

The surface quality difference between SLA and FDM comes down to how each technology builds parts:

FDM extrudes molten plastic through a nozzle, laying down material line by line. Each pass creates a tiny ridge where one bead of filament meets the next. Even with the finest nozzles (0.25mm) and thinnest layers (0.1mm), those ridges are visible to the naked eye and tangible to the touch.

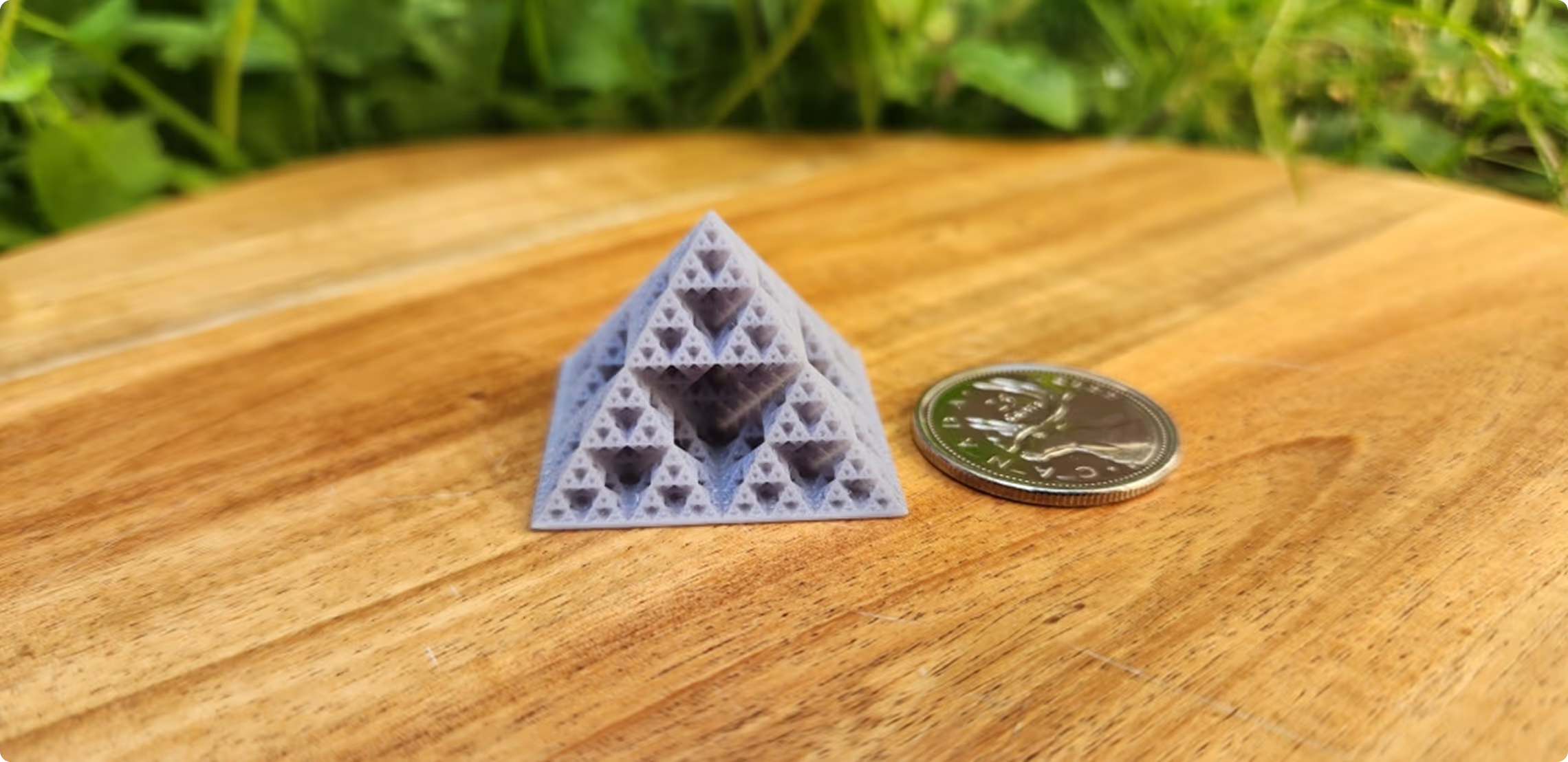

SLA uses a UV laser to cure liquid resin point by point. The laser spot is incredibly small, typically 85 microns (0.085mm), and the cured resin self-levels before each layer. The result is a surface that's smooth on a near-microscopic level.

Surface Roughness Comparison

- FDM (0.2mm layer): Ra ~15-25 μm

- FDM (0.1mm layer): Ra ~8-15 μm

- SLA (0.05mm layer): Ra ~2-4 μm

- Injection Molding: Ra ~1-2 μm

Ra = average surface roughness. Lower is smoother.

When Surface Finish Matters Most

We're not saying FDM is bad; we print thousands of FDM parts every month. But certain applications genuinely benefit from SLA's superior finish:

Client Presentations & Visual Prototypes

When you're presenting a concept to stakeholders or investors, the prototype represents your product's potential. Layer lines can make a brilliant design look like a rough draft. SLA parts photograph well, handle professionally, and communicate "finished product" rather than "work in progress."

Consumer Product Prototypes

If your final product will be injection molded, SLA prototypes give the most realistic preview of how it will look and feel. Texture, gloss, and surface detail come through clearly.

Precision Mating Surfaces

Parts that need to slide, seal, or snap together benefit from SLA's dimensional accuracy and smooth surfaces. O-ring grooves, bearing surfaces, and snap-fit features all perform better when layer lines aren't interfering with the geometry.

Investment Casting Patterns

We've printed numerous patterns for jewelry and art casting. The surface finish of the printed pattern transfers directly to the final metal casting: smooth patterns produce smooth castings.

"The detail was incredible. The jeweler couldn't believe the pattern came from a printer; he thought we'd had it hand-carved."

– Victoria jewelry designer

SLA Material Options

Beyond surface finish, SLA resins offer specialized properties for different applications:

- Standard Resin: Great all-around choice for visual prototypes. Multiple colors available.

- Tough Resin: Higher impact resistance for functional testing.

- Durable Resin: Flexible, wear-resistant for snap-fits and living hinges.

- High-Temp Resin: Heat deflection up to 238°C for molds and functional testing.

- Castable Wax: Clean burnout for investment casting applications.

- Clear Resin: Optical clarity for lenses and light pipes.

The Trade-offs

SLA isn't always the right choice. Here's when FDM might be better:

- Large parts: FDM scales more economically for bigger prints

- Functional strength: Engineering FDM materials (PA-CF, PC) often outperform resins

- Cost-sensitive production: FDM material costs are typically lower

- Outdoor use: Most SLA resins degrade in UV light without coating

The best choice depends on what matters most for your specific application. We're happy to discuss the trade-offs and recommend the right technology for your project.

Getting Started with SLA

If surface finish is important to your project, explore our SLA printing services or upload your files for an instant quote. We'll help you determine whether SLA is the right fit and recommend the best resin for your application.