You've done the hard part. Your product works. Customers want it. Reviews are positive. You've gone from prototype to pilot production to genuine demand. Congratulations: you've validated a business.

Now comes the growth ceiling.

Traditional manufacturing wisdom says: to scale, you need injection molds, CNC fixtures, dedicated assembly lines. That means six-figure tooling costs, minimum order quantities in the thousands, and months of lead time before you can react to anything.

For a brand doing $500K-$5M in revenue, that model doesn't work. You need flexibility more than you need lowest unit cost. You need to iterate based on customer feedback. You need to conserve capital for marketing and growth, not lock it up in steel molds.

The Traditional Scaling Trap

Here's the math that gets hardware brands in trouble:

A simple plastic part costs $30K-80K to tool for injection molding. You need maybe 8-12 unique parts for your product. That's $300K-900K just to manufacture what you were already making with 3D printing and hand assembly.

The promised unit cost savings are real, eventually. But they require:

- Freezing your design (no more iterations)

- Committing to minimum orders (usually 5,000-10,000 units)

- Carrying inventory (cash tied up in unsold product)

- Managing overseas suppliers (lead times, quality, IP risk)

For brands still refining their product-market fit, this is premature optimization. You're betting big before you have enough data.

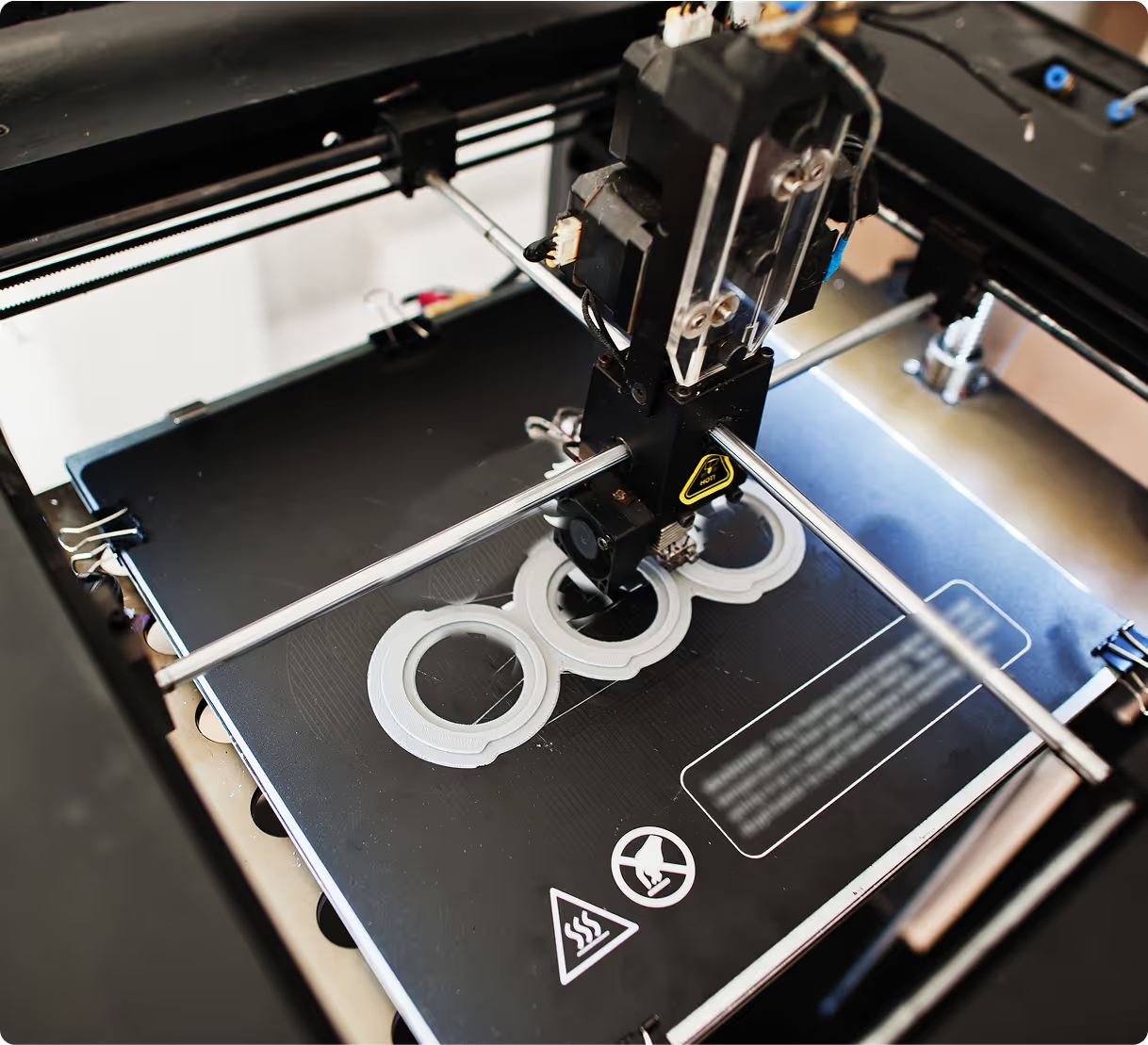

The On-Demand Alternative

On-demand manufacturing (primarily 3D printing and small-batch CNC) offers a different path:

On-Demand Manufacturing Benefits

- No tooling investment: Pay for each part individually instead of per project

- No minimums: Order 10 units or 1,000

- Design flexibility: Change dimensions, add features, fix issues

- Inventory-light: Produce closer to demand

- Geographic flexibility: Manufacture where you need it

Yes, per-unit costs are higher than injection molding at scale. But total cost of growth is often lower when you factor in iteration cycles, inventory risk, and opportunity cost of locked-up capital.

When the Math Works

On-demand manufacturing makes the most sense when:

Your volumes are in the "awkward middle"

Too big for one-off prototyping, too small for injection molding. If you're shipping 50-5,000 units per year of a given SKU, on-demand is often the economic winner.

Your design is still evolving

Customer feedback is gold. If you're still learning what people want, the ability to iterate quickly is more valuable than optimized unit costs.

You have multiple SKUs or customization

Traditional manufacturing loves uniformity. If your product line includes variations (sizes, colors, configurations) on-demand handles this naturally.

Cash conservation matters

Every dollar in tooling is a dollar not spent on growth. For bootstrapped or early-stage companies, capital efficiency often trumps unit economics.

The Hybrid Path

Smart brands don't choose one approach forever. They use on-demand manufacturing strategically:

- Launch with 3D printing to validate demand and refine the product

- Scale with on-demand through the growth phase

- Tool selectively only for high-volume, stable components

- Keep flexibility for accessories, spares, and new variants

This hybrid approach lets you move fast early, then optimize where it matters most once you have data.

Real Numbers

Let's compare two approaches for a brand selling 2,000 units annually:

Traditional Approach

- Tooling: $150,000

- MOQ: 5,000 units @ $8/unit = $40,000

- Inventory carrying cost: ~$4,000/year

- Lead time: 4-6 months initial, 6-8 weeks reorder

- Year 1 total: $194,000

On-Demand Approach

- Tooling: $0

- 2,000 units @ $25/unit = $50,000

- Inventory: minimal (produce monthly)

- Lead time: 2-5 days

- Year 1 total: $50,000

The traditional approach only breaks even at roughly 8,000+ units, assuming the design doesn't change. For many brands, that break-even point is 3-4 years away, if ever.

Making It Work

To scale successfully with on-demand manufacturing:

- Design for the process: Parts optimized for 3D printing or CNC will cost less and perform better

- Build supplier relationships: Volume brings better pricing and priority

- Standardize where possible: Use common fasteners, materials, and dimensions

- Keep good records: Version control your designs so you can reproduce exactly what you shipped

"We grew from 500 to 3,000 units per year without any injection molds. The flexibility let us improve the product three times based on customer feedback. When we finally did tool one part, we knew the design was rock-solid."

– Hardware startup founder

Getting Started

If you're hitting the growth ceiling and wondering how to scale without massive capital investment, let's talk. We help brands navigate from prototype through production, choosing the right manufacturing approach at each stage.

Contact us to discuss your scaling strategy, or upload your files for production pricing.